18

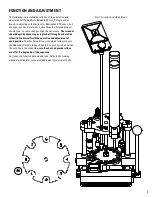

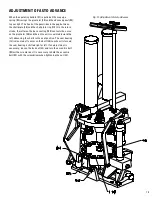

CONVERTING TO ANOTHER GAUGE

If you purchase a die set for a different gauge, always

remember to start installation by adjusting the full length size

die (14) FIRST! When adjusted properly, the size die should just

contact the platen (107) at the top of the stroke . Then, install

other dies and punches using the size die (14) as a guide .

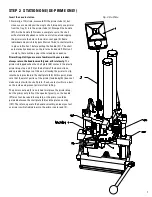

Stations should be adjusted by actually reloading a shell . The

exception is the primer seating pad (3) to ensure seating the

primer to the full depth of the primer pocket . Adjust the wad ram

(46) to provide best crimp (except as noted in sinking crimps or

bulging) .

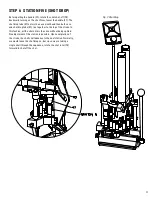

By showing you how to “fine tune” and troubleshoot the

366 Auto, we hope to save you downtime and maximize your

reloading enjoyment . Your 366 Auto is a fine progressive

reloader…once the first cycle is completed; it kicks out a

finished shell with every stroke .

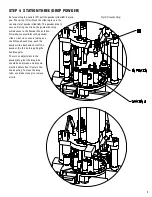

ABOUT WADS AND WAD PRESSURE:

We recommend the use

of 1-piece plastic wads . They are more convenient, and do not

require any specific wad pressure . They need to be seated only

deep enough to obtain a satisfactory crimp .

PLEASE NOTE:

Normally, few problems are encountered when

reloading shot shells . However, variations in the powder lot,

different brands of primers and other components can cause

substantial changes in pressure . Hornady Manufacturing

Company has no control over the components and equipment

which may be used with this published information; no

responsibility is implied or assumed for modern firearms and

does not exceed manufacturer’s pressure recommendations .

Further data may be obtained from:

• www .hodgdon .com

• www .imrpowder .com

• www .alliantpowder .com

• www .accuratepowder .com

• www .wwpowder .com

• www .ramshot .com