10

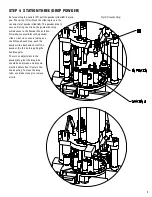

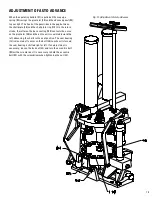

STEP 5: STATION FOUR (WAD SEATING)

Insert a wad in the wad guide (106A) . Pull the operating handle

(37) through a complete stroke . When the handle (37) is

pulled, the spring (106B) around the wad guide rod (105)

turns the wad guide bracket (101) to align the wad with

the case . The unit then rises until the wad is stopped

with the platen casting (107) by the wad ram (48) .

The case continues upward until the spring fingers

(77) have entered the case mouth, and then

pushes the wad guide (101) upward until the wad

is seated in the case . The spring fingers (77)

have enough resistance to prevent the wad

from going through until the spring fingers (77)

are in the case . At the completion of the return

stroke, the wad guide bracket (101) will swing

forward for the next wad to be inserted .

The

wad guide bracket should have 1/8" clearance

above the shells.

The empty shells vary in length

so a closer setting would not be beneficial .

Be sure

the wad seating ram (48) is set high enough for the

wad to swing into position with out being folded by

early contact with the wad seating ram (48).

Wad pressure is adjusted by raising or lowering

the wad seating ram (48).

Most one-piece

plastic wads today will self-adjust when the

shell is crimped .

Generally, the wad should

be seated to allow 5/8" clearance between

the case mouth and the shot.

Fig. 6: Wad Seating