U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

32-00015—05

14

Safety Function of the U2-S Model

The safety function of the U2-S signal processor consists

of a Flame Relay which comprises its safety function and

behaves as follows:

The Flame Relay (Normally Open)

• The Flame Relay will be energized when the product is

powered and a flame on condition is detected for longer

than the time delay value.

• The Flame Relay will be de-energized when the product

is powered, a flame off condition is detected, and the

FFRT (Flame Failure Response Time) has elapsed.

• The Flame Relay will be de-energized when the product

is powered and detects a fault condition.

• The Flame Relay will be de-energized when power to

the product is off.

All U2-S signal processor models contain a Self Check

Relay designed to be energized during normal operation

and de-energized during power off, or detection of a fault.

Proof Test Interval

The Proof test must be conducted every 1 to 5 years. This

range is given to allow for the test to be performed during

the normally scheduled burner shutdown period. It is the

responsibility of the user to perform the proof test in the

specified time frame.

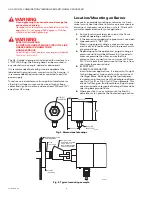

The following chart for the U2-1010S shown for example,

presents the dependence of the PFD

AVG

on the proof test

interval. The PFD

AVG

increases as the proof test interval

increases.

Fig. 8. 1010S PFD

AVG

over time.

Proof Test Procedure

EQUIPMENT REQUIRED

• Powered Uniscan 2S signal processor

• Multimeter capable of voltage measurements < 50V,

and resistance measurements 1 Ohm to 1MOhm. Fluke

87 or similar.

• 24V DC Power supply < 500mA

• Light source* capable of generating a flame on

condition for all sensors.

* Use an incandescent bulb for IR sensor, deep UV light for

solid state UV and UV tube sensors. If none of these are

available a flame may be used. Note that IR, and SSUV

sensors require flickering light source.

Setup

1.

Set power supply to OFF. Connect U2-S model to

power supply as described in manual.

2.

While performing the proof test, disconnect or disre-

gard the signal processor so that any outputs due to

testing do not affect the overall safety system and

potentially cause a hazardous situation.

3.

Record all previously entered user programmable

settings so that they may be restored after the proof

test.

Tests

1.

Ensure that power is completely removed form the

U2-S. Measure resistance between yellow and green

wires and verify that self check relay contact is open

circuit ( >1MOhm ). Measure between green and

gray, and verify flame relay contact is open circuit (>

1MOhm).

2.

Reapply power to the signal processor and, using a

multimeter, ensure closure of the self check relay by

measuring continuity * between the yellow and

green wires.

* Less than ~5ohm / 50foot cable

3.

Use a light source to generate a flame on condition

and, using a multimeter, ensure closure of the flame

relay by measuring continuity between the green

and gray wires.

4.

Remove any light source to generate a flame off con-

dition and, using a multimeter measure resistance

between green and gray wires, and verify flame relay

contacts are open ( > 1MOhm), after the FFRT

(Flame Failure Response Time) has elapsed.

5.

Measure the current draw of the U2 and ensure it is

less than 120 mA.

6.

Change FFRT settings of the signal processor and

store the changed setting. Remove power to the sig-

nal processor for 10 seconds. Restore power to the

signal processor and ensure the stored value has

remained unchanged.

MCR35675

0

1

2

3

4

5

6

7

8

9

10

PFDavg

U2-1010S TIME IN YEARS VS PFDavg

2.53E-04

2.03E-04

1.53E-04

1.03E-04

5.27E-05

2.71E-06