4. Set Up and Calibration Procedures - Setting End-of-Travel Limit Switches (actuators mfd. pre-1/1/03)

Revision 5

10260S HercuLine® Actuator Installation, Operation and Maintenance Manual

67

7/07

Setting End-of-Travel Limit Switches (actuators mfd. pre-1/1/03)

WARNING

While the unit is powered, a potentially lethal shock hazard exists inside the case.

ATTENTION

The first two cams (starting from the back) are for the 0 % and 100 % limit switches and should not need

any adjustments as they are factory set to stop the drive at 0 % and 100 %.

To adjust the limit switch cams (see Figure 20):

1.

Remove the cover. (Non-contact sensor and terminal cover, see Figure 1.)

2.

Turn the locking nut, found behind the sensor, counter-clockwise using a 1/8” allen wrench or the

equivalent inserted into the radial holes in the locking nut until it is possible to turn the cams with your

fingers.

3.

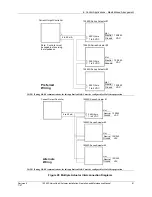

Using a slotted screwdriver on the slots at the edge of the cams, or your finger, rotate the cams until the

switches are set. (See Figure 21 .)

•

Rotate the actuator shaft, using the manual handwheel or the auto/manual switch, to the 0 %

position (this is the 0 % for CCW operation using the left-hand scale or 100 % for CW operation

using the right hand scale). If the actuator is installed on a damper or valve, also make sure that

this position is synchronized with the travel of the final control element.

•

Rotate the #1 limit switch operating cam to activate at this position. The switch roller arm should

go from being in an up, not depressed state, to a depressed state as the cam is rotated in the

direction of the shaft rotation going toward the limit position. This will cause the switch to go

from NC to NO and turn off the power to the motor when the switch activates. Switch activation

may be detected by the clicking sound or with a continuity tester connected to the terminals. Both

the NC and NO contact states are available to the customer at the terminals (see Figure 13 page

26).

•

Rotate the actuator shaft, using the manual handwheel or the auto/manual switch, to the 100 %

position (this is 100 % for CCW operation using the left-hand scale or 0 % for CW operation

using the right hand scale). If the actuator is installed on a damper or valve, also make sure that

this position is synchronized with the travel of the final control element.

•

Rotate the #2 limit switch operating cam to activate at this position. The switch roller arm should

go from being in an up, not depressed state, to a depressed state as the cam is rotated in the

direction of the shaft rotation going toward the limit position. This will cause the switch to go

from NC to NO and turn off the power to the motor when the switch activates. Both the NC and

NO contact states are available to the customer at the terminals (see Figure 13 page 26).

•

If optional auxiliary switches were ordered, these switches may also be set at this time. (See page

70 for details of setting auxiliary switches.)

4.

Once the cams are set in the correct positions, turn the locking nut clockwise until snug tight (it does

not have to be “hard” tight and does not have to completely flatten the spring washer).

5.

Double check limit switch actuation by first manually driving the actuator to each end of travel and

hearing the switch click or by detecting it with a continuity tester. Secondly, drive the actuator to both

ends of travel (using the auto/manual switch or by providing minimum and full input signal) and make

sure the switches activate and turn off the motor.

Summary of Contents for HercuLine 10260S

Page 10: ......

Page 94: ......

Page 121: ......

Page 122: ...Honeywell Field Solutions Honeywell Inc 512 Virginia Drive Fort Washington PA 19034 ...