Function Blocks

PID Function Block

Revision 11

HC900 Hybrid Control Designer Function Block Reference Guide

273

2/07

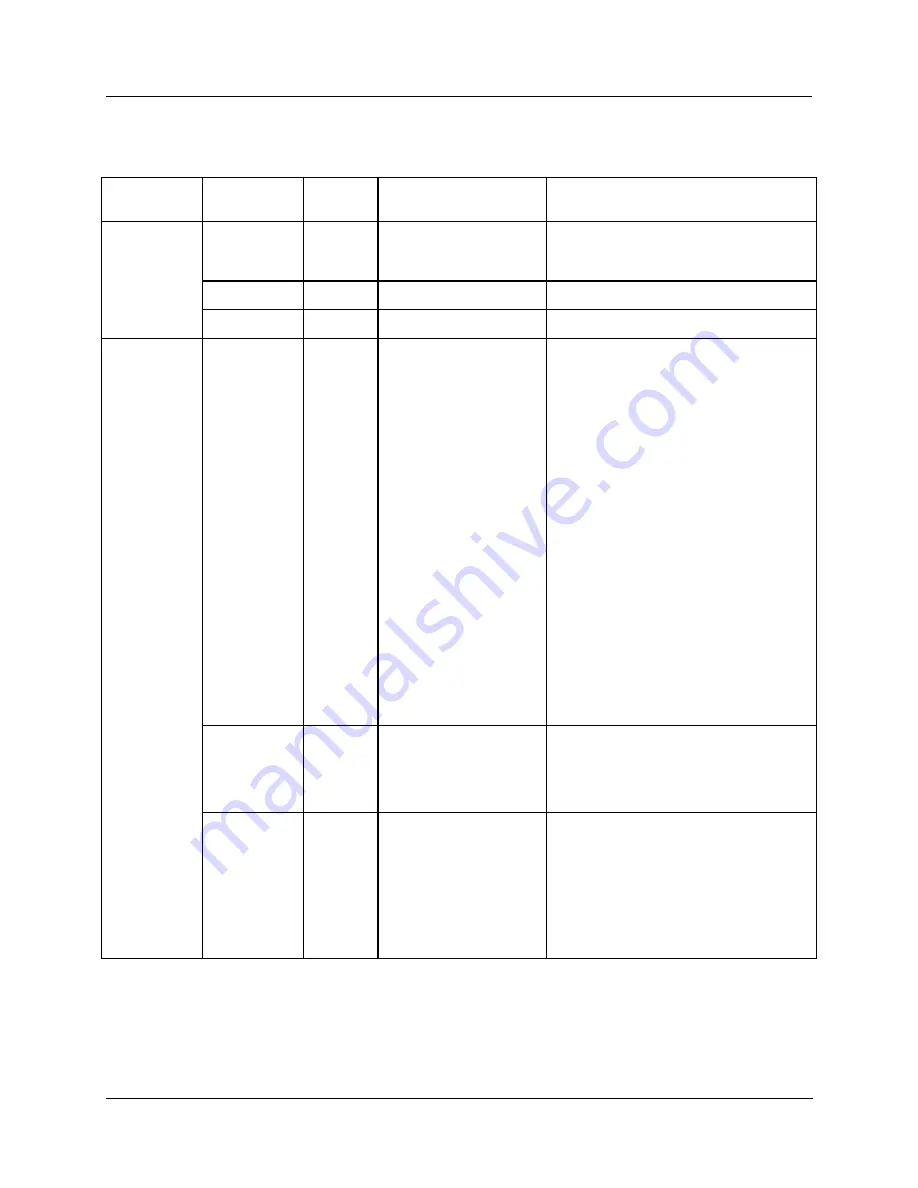

Table 79 PID General tab configuration parameters

Properties

Group

Parameter

Index #

Parameter Description

Value or Selection

Block Order

N/A Execution

Order

Read Only. To change block order, right-

click on a Function Block and select

Execution Order.

Tag

Name

N/A

16 character tag name

Descriptor

N/A Block

descriptor

Control Algorithm

N/A Control

Algorithm

Note: In PID B, step

changes in setpoint

will not bump the

output; the output will

slew smoothly to the

new value.

In PID A, a step

change in setpoint will

result in a step change

in output

.

PID A

- is normally used for 3 mode

control. The output can be adjusted

somewhere between 100 % and 0 %. It

applies all three control actions -

Proportional (P), Integral (I), and

Derivative (D) - to the error signal.

PID B

- Unlike the PID-A equation, the

controller gives only an integral response

to a setpoint change, with no effect on

the output due to the Gain or Rate action,

and gives full response to PV changes.

DUPA -

like PID A but provides an

automatic method to switch tuning

constant sets for Heat/Cool applications.

DUPB -

like PID B but provides an

automatic method to switch tuning

constant sets for Heat/Cool applications.

NOTE: With PID B or DUPB selection,

you

will not

be allowed to set RESET or

RPM to 0.00 (OFF). Reset must be

enabled.

Direction

N/A Control

Action

DIRECT

- PID action causes output to

increase

as process variable increases.

REVERSE

- PID action causes output to

decrease

as process variable increases.

SP

Tracking

N/A Setpoint

Tracking

None

Track PV

- When control mode is

“manual”, local setpoint tracks process

variable.

Track RSP

- When setpoint is “remote

setpoint”, local setpoint tracks remote

setpoint.