OPERATION

HOLZMANN MASCHINEN GmbH www.holzmann-maschinen.at

68

ED1080ADIG

Clamping the workpiece

1.

Disconnect the machine from the mains.

2.

Place a stable board or chuck cradle under the spindle to protect the precision-ground

surfaces.

3.

Insert the chuck key into a scroll groove and turn it counterclockwise to open the jaws

until the workpiece lies flat on the clamping surface or evenly on the jaw steps or fits into

the chuck hole and through the spindle hole.

4.

Close the jaws until they make light contact with the workpiece.

5.

Turn the chuck by hand to ensure that the workpiece is held evenly by all three jaws and

centred on the chuck.

If the workpiece is not centred, release the jaws and realign the workpiece. Retighten the jaws

and repeat step 5. When the workpiece is centred, fully tighten the jaws.

18.9.1

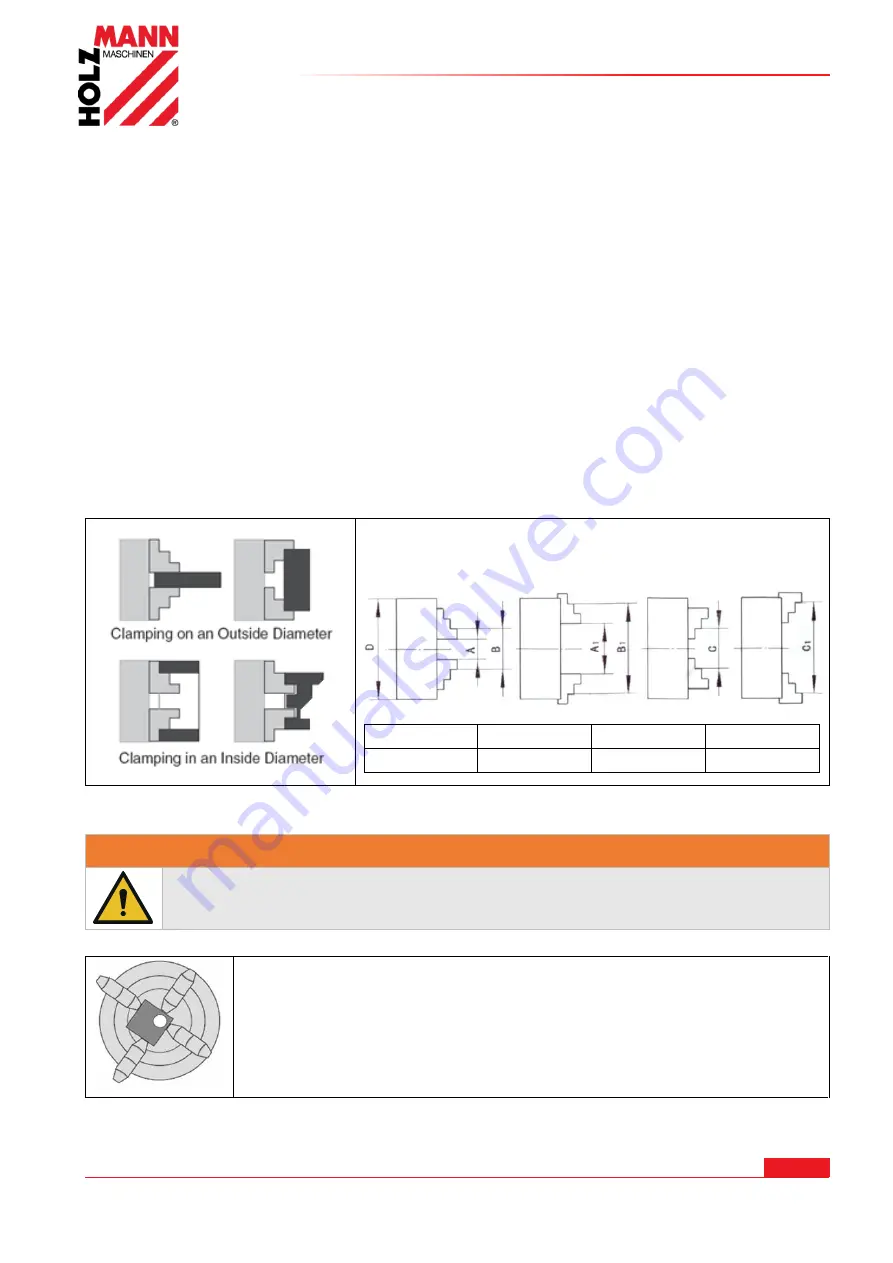

3-jaw chuck

The 3-jaw chuck supplied with your machine is a scroll chuck, i.e. all three jaws move uniformly

when the chuck key is turned. This jaw configuration is used to hold concentric workpieces that

are centred with the same pressure from all three jaws. A set of reversible top jaws is also

included to allow additional workpiece configurations.

Both sets of jaws can accommodate a workpiece on both

the inside and outside - see illustration on the left.

Regardless of how you configure the jaws, make sure the

workpiece is firmly clamped in the jaw chuck.

Ø D

A – A1

B – B1

C – C1

200 mm

4 – 120 mm

50 – 220 mm

60 – 230 mm

18.9.2

4-jaw chuck

W A R N I N G

Use the 4-jaw chuck only for low-speed turning operations. If the 4-jaw chuck is used

at medium or high speed, unbalance will almost always occur and the operator or

bystanders may be hit by an ejected workpiece.

The 4-jaw chuck has independently adjustable jaws. This means that non-

cylindrical parts can be held for facing or drilling and brought into the

spindle centre line. A further advantage is that the majority of workpieces

can be positioned outside the spindle rotation axis, e.g. when a hole or step

on an outer edge has to be cut into a workpiece.

For optimum grip on non-cylindrically shaped workpieces, one or more jaws

can also be rotated 180° to gain more clamping area.

Summary of Contents for ED1080ADIG

Page 84: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 84 ED1080ADIG 2...

Page 85: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 85 ED1080ADIG...

Page 86: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 86 ED1080ADIG...

Page 87: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 87 ED1080ADIG...

Page 88: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 88 ED1080ADIG 6...

Page 93: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 93 ED1080ADIG 2...

Page 94: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 94 ED1080ADIG 3...