CLEANING

HOLZMANN MASCHINEN GmbH www.holzmann-maschinen.at

71

ED1080ADIG

18.9.9

Thread cutting

Threading or tapping requires good turning skills and

sufficient experience from the operator.

See the following example

Example outside thread:

The workpiece diameter must be turned to the diameter of the desired thread.

The workpiece requires a chamfer at the beginning of the thread and an undercut at the

end of the thread.

The speed must be as low as possible.

The thread chisel must correspond exactly to the thread form, be absolutely right-angled

and clamped exactly to the turning centre.

The engagement lever for thread cutting must remain closed during the entire thread

cutting process. Excluded are the thread pitches which can be carried out with the tapping

watch.

The thread is produced in several cutting operations, so that the turning tool must be

completely turned out of the thread (with the facing slide) at the end of a cutting

operation.

The return path is made with the clasp nut closed and the thread turning tool not engaged

by actuating the "Shift lever Direction of rotation".

Switch off the machine and reposition the chisel in small cutting depths with the cross

slide.

Before each run, adjust the upper slide by approx. 0.2 to 0.3 mm alternately to the left

and right in order to free the thread. The thread chisel therefore only cuts on one thread

flank in each pass. Do not cut free until shortly before reaching the full thread depth.

19

CLEANING

N O T I C E

Wrong cleaning agents can attack the varnish of the machine. Do not use solvents,

nitro thinners, or other cleaning agents that could damage the machine's paint.

Observe the information and instructions of the cleaning agent manufacturer!

Prepare the surfaces and lubricate the bare machine parts with an acid-free lubricating oil.

Regular cleaning is a prerequisite for the safe operation of the machine and its long service life.

Therefore, clean the device after each use of chips and dirt particles.

20

MAINTENANCE

W A R N I N G

Danger due to electrical voltage! Handling the machine with the power supply up

may result in serious injury or death. Always disconnect the machine from the power

supply before servicing or maintenance work and secure it against unintentional

restart!

The machine is low-maintenance and only a few parts have to be serviced. Nevertheless, any

faults or defects which may affect the safety of the user must be rectified immediately!

Summary of Contents for ED1080ADIG

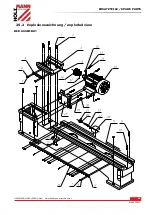

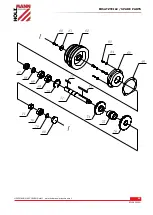

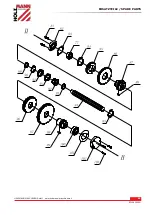

Page 84: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 84 ED1080ADIG 2...

Page 85: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 85 ED1080ADIG...

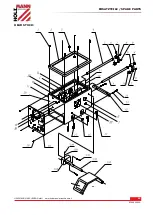

Page 86: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 86 ED1080ADIG...

Page 87: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 87 ED1080ADIG...

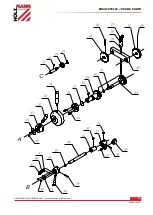

Page 88: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 88 ED1080ADIG 6...

Page 93: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 93 ED1080ADIG 2...

Page 94: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 94 ED1080ADIG 3...