--- 36 ---

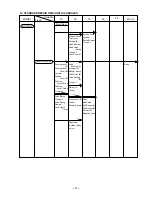

11. INSPECTION AND CONFIRMATION AFTER REASSEMBLY

Check that Plunger (A) [59] moves smoothly.

Check that there is no air leakage from each part.

While driving nails with an air pressure of 4.5 kgf/cm

2

(63 psi), check that there is no idle driving and bending

of nails.

Note: Before conducting the driving test, turn Adjuster [44] to the deepest position.

Recheck the tightening torque of each screw.

Check that Pushing Lever (A) [31] slides smoothly.

Check that the machine will not operate only by pulling the Trigger [39]. Also check that the machine will not

operate only by depressing Pushing Lever (A) [31].

Push Nail Stopper (A) [90] and Nail Stopper (B) [92] with fingers to check that they smoothly return to position.

Check that the Feed Piston [64] operates properly at 5 kgf/cm

2

(70 psi. 4.9 bar) (Open the Nail Guide [89] and

perform idle driving.).

Check that the Trigger [39] moves smoothly.

Check that the Adjuster [44] turns smoothly.

Summary of Contents for NV 75AG

Page 45: ......