--- 27 ---

(b) Reassembly

Disassembly procedures should be followed in the reverse order. Note the following points:

Be extremely careful to prevent the entry of foreign particles into the control valve section.

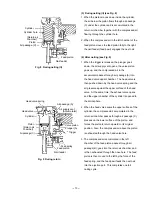

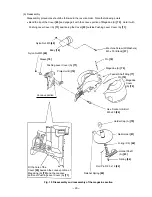

Thoroughly apply grease to the O-Ring (I.D 1.8) [60] on Plunger (A) [59], O-Rings (I.D 11) [56], (S-18) [54]

and (S-4) [48] on Valve Piston (B) [57], and the shaft of Plunger (A) [59] as shown in Fig. 17.

As shown in Fig. 17, install Valve Bushing (A) [61] so that the roll pin groove in Valve Bushing (A) [61] will be

aligned with the roll pin hole in the Body [18]. First, insert a roll pin puller (3 mm (0.118") dia.) into the roll pin

hole. Then, upon confirming that the puller passes through the hole, drive in the Roll Pin D3 x 28 [38].

If an attempt is made to drive the roll pin with force when the roll pin groove in Valve Bushing (A) [61] is not

aligned with the roll pin hole in the Body [18], it will damage the periphery of Valve Bushing (A) [61] and

prevent disassembly or reassembly.

After assembling, check that Plunger (A) [59] moves smoothly.

Fig. 17

Plunger (A) [59]

Valve Bushing (A) [61]

Valve Bushing (A) [61]

Roll pin

groove

Coat the O-ring

groove's shaft

with grease.

Roll Pin D3 x 28 [38]

Body [18]

Apply grease to the stem.

Roll pin hole

Summary of Contents for NV 75AG

Page 45: ......