DC Motor Removal and Replacement 11

DC MOTOR REMOVAL AND REPLACEMENT

WARNING: Disconnect Vehicle Battery

prior to performing this procedure to

avoid electrical shock or burns.

1

2

PHOTO NO. 1000322A

Disconnect the vehicle negative battery termi-

nal wire (solid black). Remove motor terminal

nut and remove power lead (solid red or red-

striped).

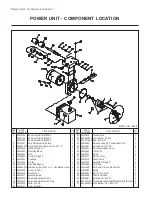

MOUNT BOLTS

PHILLIPS HEAD SCREWS

MOTOR CAP

MOTOR

DWG NO. 3512

Remove the two Phillips head screws from the

motor cap. Using a 3/8” wrench loosen the two

motor mounting bolts. Do not remove bolts.

NOTE:

Use care when removing the motor from

the endhead, the motor can separate into three

pieces and will require additional time to reas-

semble.

Hold motor together while removing it from the

end head.

NOTE:

If oil is found in the cavity of the valve

passage where the coupling is located, replace-

ment of the oil pump shaft seal is necessary be-

fore the unit can be put back into service.

See page 20.

PHILLIPS HEAD SCREWS

MOTOR CAP

MOTOR

MOTOR TERMINAL

(POS)

GROUND SCREW

(NEG)

COUPLING

PUMP SHAFT

VALVE PASSAGE

SHIPPING NUTS

(REMOVE)

DWG NO. 3513

Remove shipping nuts from new motor, align

splined shaft of motor with coupler and position

motor onto the location pins on the end head.

Torque the two motor mounting bolts to 5-8 ft.

lbs. with a 3/8” wrench. Reattach motor cap.

Reconnect the vehicle negative battery terminal

wire (solid black) and the power lead (solid red

or red striped). See photo 1000322A.