84

Error

Description

Reason

Solution

E686

Stepping

closed

‐

loop

DSP1X25

is

out

of

track

The

position

detected

by

the

encoder

isn’t

accord

with

the

one

in

the

program

The

stepper

motor

to

open

loop

mode,

if

can

be

normal

work,

the

motor

is

normal.

If

the

machine

can't

normally

work,

you

may

need

to

troubleshoot

step

plate

part

and

motor

ontology.

After

finish

the

above,

troubleshoot

the

encoder

part,

to

see

if

the

encoder

cables

plugged

into

the

wrong,

if

stuck,

is

there

any

encoder

signal

damaged

or

step

plate

feedback

signal

damaged

part

or

if

encoder

ontology

is

normal.

E687

Stepping

closed

‐

loop

DSP1X25

is

over

‐

speed

Over

‐

speed

is

detected

Please

refer

to

E686

E690

Stepping

closed

–loop

communication

is

abnormal

DSP2(X21/X23)

Received

instructions

failed

checking

。

Please

check

if

the

SPI

communication

cable

is

connected

well

or

not.

E691

Stepping

closed

‐

loop

DSP2X23

is

overload

Overcurrent

is

detected

Please

check

if

the

motor

is

in

good

condition

through

checking

its

resistance

and

inductance

,if

it

is

well,

please

check

the

stepping

driving

board

E692

Stepping

closed

‐

loop

DSP2

first

(X23)

is

overloaded

The

position

detected

by

feedback

of

encoder

doesn’t

conform

to

instruction

of

the

procedure.

The

stepper

motor

to

open

loop

mode,

if

can

be

normal

work,

the

motor

is

normal.

If

the

machine

can't

normally

work,

you

may

need

to

troubleshoot

step

plate

part

and

motor

ontology.

After

finish

the

above,

troubleshoot

the

encoder

part,

to

see

if

the

encoder

cables

plugged

into

the

wrong,

if

stuck,

is

there

any

encoder

signal

damaged

or

step

plate

feedback

signal

damaged

part

or

if

encoder

ontology

is

normal.

E693

Stepping

closed

‐

loop

DSP2

first

(X23)

over

speed

The

working

rotate

speed

abnormal

is

detected

through

the

feedback

signal

from

the

encoder

The

same

test

method

with

above

E695

Stepping

closed

‐

loop

DSP2

first

(X21)

over

current

Hardware

detect

a

large

current

First

check

whether

the

motor

is

normal,

can

measure

the

resistance,

inductance

values

if

they

are

within

the

normal

range.

If

the

motor

is

normal,

need

to

check

if

the

stepping

board

hardware

is

normal.

Summary of Contents for HK2900

Page 1: ......

Page 7: ...6 缝纫机机头 布压脚 线架装置 操作盘 电源开关 控制箱 踏板开关 2 各部的名称 1 主机的名称 ...

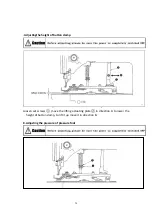

Page 23: ...22 外部线缆插头上有对应的编号 请仔细查看后对应接插 示意图 5 6 图 5 图 6 10 电缆线的链接 ...

Page 24: ...23 11 马达护罩的安装 把马达护罩 用附属的螺丝安装到缝纫机主体上 12 电线的处理 放倒缝纫机时 请确认机头支杆安装在机台上 在放倒缝纫机的状态 连接电线 如图所 示用线束夹 捆紧 ...

Page 27: ...26 穿过机针的线应留出 4cm 左右 3 上线的穿线方法 4 梭壳的取下插入 1 打开旋梭外罩 2 拨起旋梭壳 的抓脚 取出梭壳 3 插入时 请把梭壳深深插入旋梭轴 并关 闭抓脚 ...

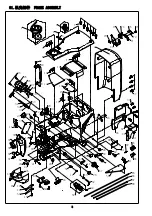

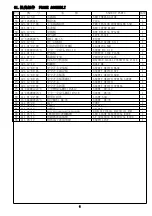

Page 76: ...75 机台台板 ...

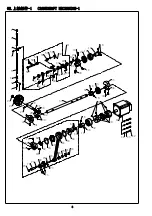

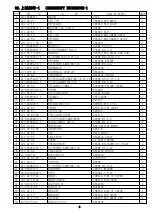

Page 93: ...12 2 Operation ...

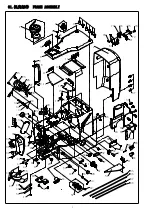

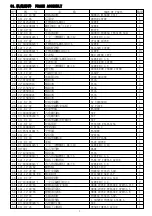

Page 169: ...88 Table diagram ...

Page 170: ......

Page 194: ...2 4 5 6 7 9 2 3 6 8 1 23 HK2903 专用附件 EXCLUSIVE ACCESSORIE PARTS FOR HK2903 ...