14.

Install the server into the chassis (

on page 14).

15.

Press the Power On/Standby button.

The server exits standby mode and applies full power to the system. The system power LED changes

from amber, to flashing green, and then to green.

16.

If applicable, install an I/O module into the chassis (

Installing an I/O riser module

on page 40).

Installing an I/O riser module

I/O modules are specific to each server and are installed in the rear of the chassis.

The server supports the HPE XL230k External I/O Module when one of the following options are installed:

• HPE XL230k x16 LP PCIe External I/O Riser Kit

• HPE XL230k x8 PCIe Internal-External I/O Riser Kit

For more information about product features, specifications, options, configurations, and compatibility, see the

product QuickSpecs on the Hewlett Packard Enterprise website (

).

CAUTION:

To prevent electrical damage, always power down the server associated with the I/O module

before installing the I/O module.

CAUTION:

Remove the server from the chassis before installing the I/O module. Failure to do so can

result in damage to both components. After the I/O module is installed, install the server.

IMPORTANT:

Microsoft Windows does not include native support for certain expansion cards that can

be installed in the I/O module. For more information about enabling support, see the Hewlett Packard

Enterprise website (

http://www.hpe.com/support/XL230k-io

).

IMPORTANT:

The left and right sides of the chassis are oriented 180° from each other. Components

that are installed on one side of the chassis must be turned 180° when they are installed on the opposite

side.

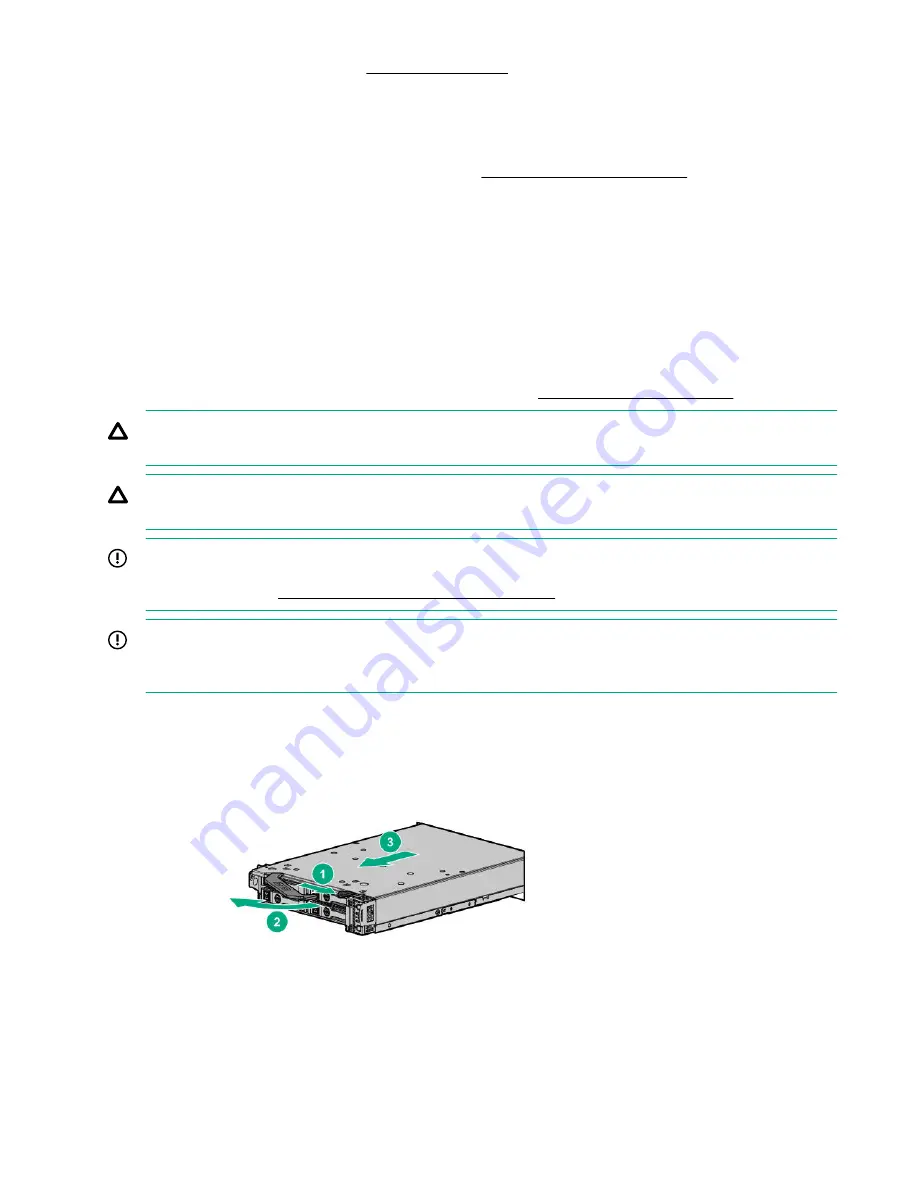

Procedure

1.

Power down the server associated with the I/O module.

2.

Remove the server from the chassis.

3.

At the rear of the chassis, remove the I/O module riser blanks.

40

Hardware options installation