WARNING: To reduce the risk of electric shock, fire, and damage to the equipment, you must install this product in

accordance with the following guidelines:

• This power supply is intended only for installation in Hewlett Packard Enterprise systems located in a restricted

access location.

• This power supply is not intended for direct connection to the DC supply branch circuit. Only connect this power

supply to a power distribution unit (PDU) that provides an independent overcurrent-protected output for each DC

power supply. Each output overcurrent-protected device in the PDU must be suitable for interrupting fault current

available from the DC power source and must be rated no more than 40A.

• The PDU output must have a shutoff switch or a circuit breaker to disconnect power for each power supply. To

completely remove power from the power supply, disconnect power at the PDU. The end product may have multiple

power supplies. To remove all power from the product, disconnect the power for each power supply.

• In accordance with applicable national requirements for Information Technology Equipment and

Telecommunications Equipment, this power supply only connects to DC power sources that are classified as SELV or

TNV. Generally, these requirements are based on the International Standard for Information Technology Equipment,

IEC 60950-1. In accordance with local and regional electric codes and regulations, the DC source must have one pole

(Neutral/Return) reliably connected to earth ground.

• Connect the power supply ground screw located on the front of the power supply to a suitable ground (earth)

terminal. In accordance with local and regional electric codes and regulations, this terminal must be connected to a

suitable building ground (earth) terminal. Do not rely on the rack or cabinet chassis to provide adequate ground

(earth) continuity.

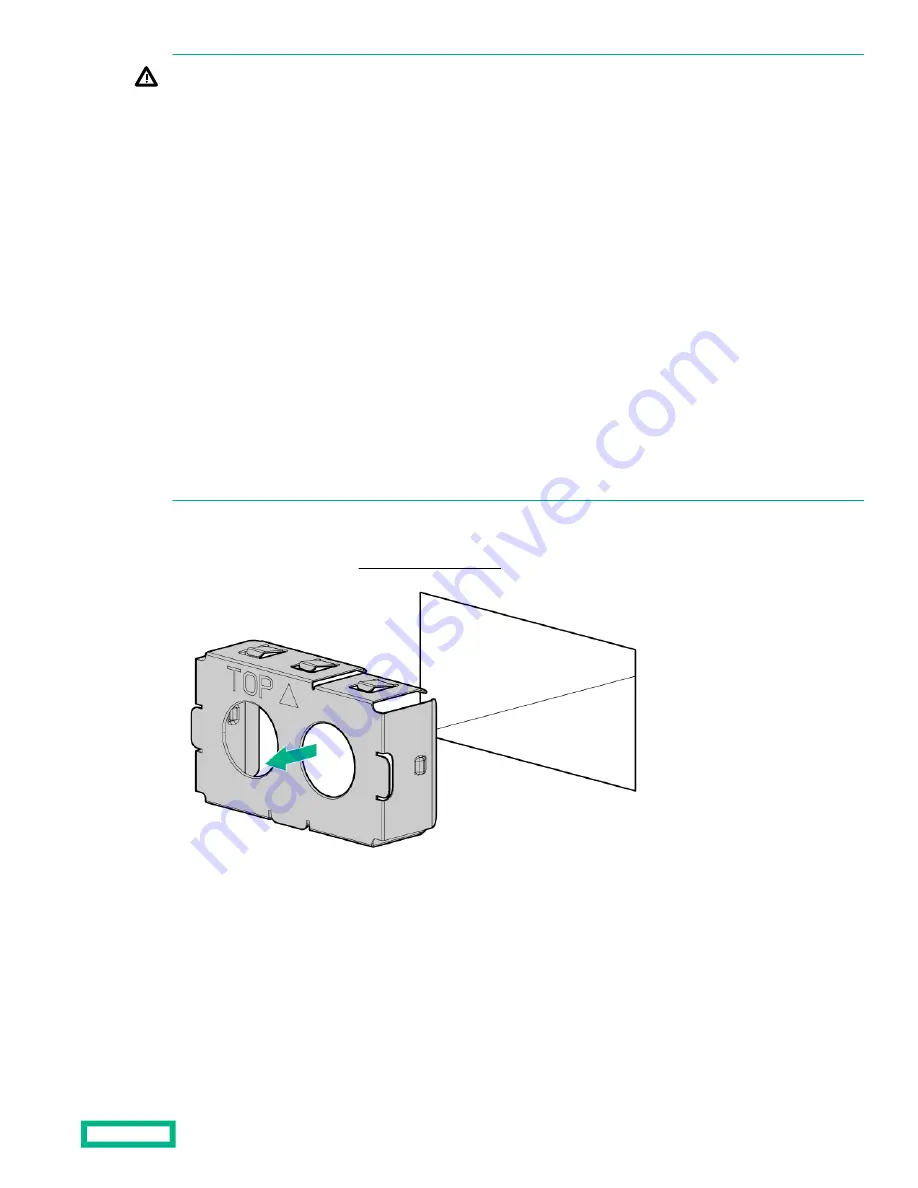

Procedure

1.

Remove the power supply blank (

2.

Remove the ring tongue.

Hardware options installation

103