Safety

13

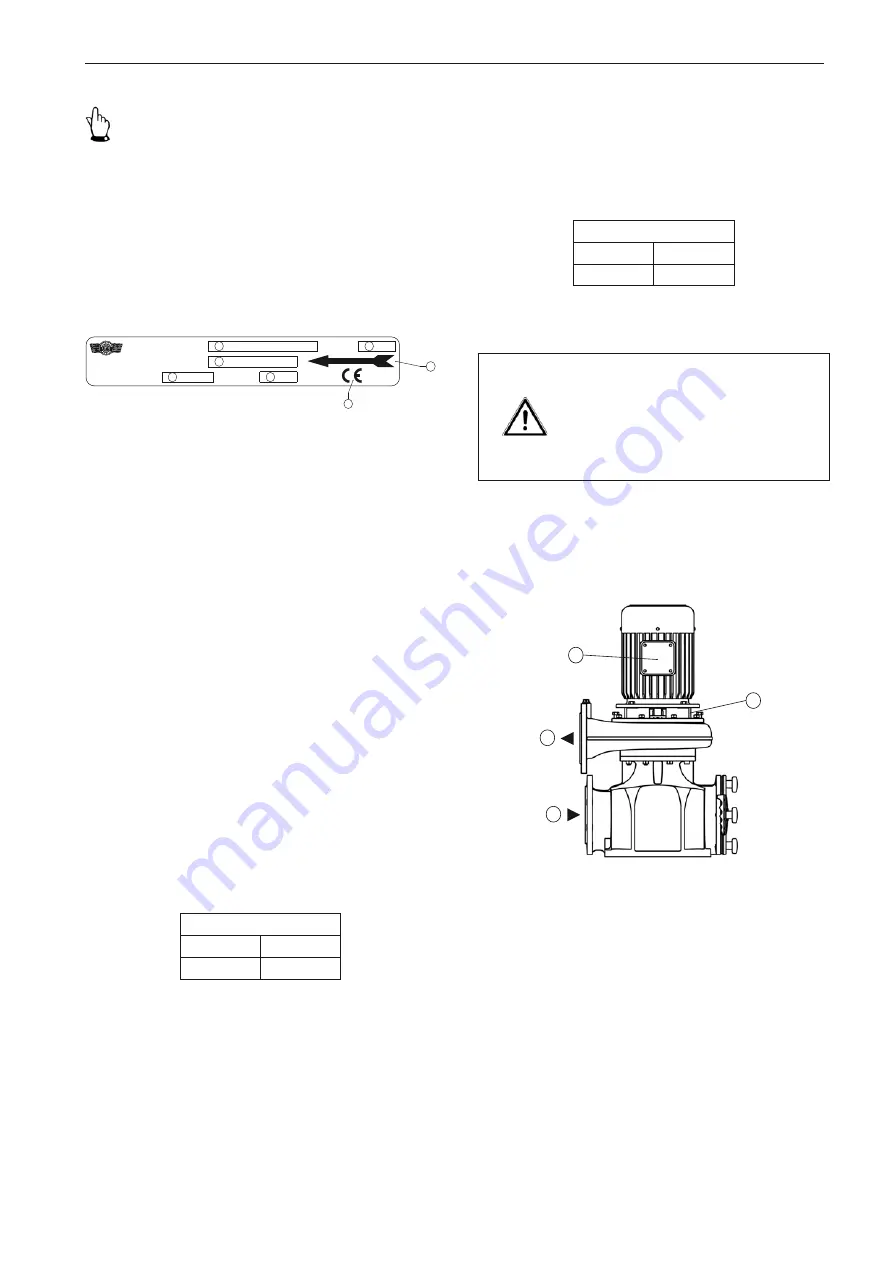

Figure 2 Name plate

Key to figure 2

1. Model designation

2. Year of manufacture/ month

3. Order No.

4. Nominal flow rate

[m

3

/h]

5. Nominal head

[m]

6. CE symbol

7. Observe the direction of rotation!

2.2

Integrated safety systems (optional)

Check the integrated safety devices in regular inspection

intervals

j

= annually.

The inspection methods applied here are:

S

= Visual inspection,

F

= Functional check.

Winding protection

If the pump is also equipped with thermal winding protec-

tion with direct temperature monitoring, this switches off the

pump's motor if it starts to get too hot.

Inspection

Interval

Method

j

S, F

Important!

When making any inquiries and ordering spare parts

please make sure you specify the pump type and the order

number.

Also observe the name plate on the motor.

The name plate is attached to the fan hood or the motor

housing (UNIBAD-XC).

ETS X4

An existing ETS X4 (electronic dry running protection system)

that uses a vibrating fork sensor prevents the dry running

of the slide ring seal. This protects the functionability of the

pump.

Inspection

Interval

Method

j

S, F

Caution!

Incorrect warming will damage the

three-phase motor.

Do not decommission safety equipment

or change its mode of operation.

2.3

Connections on the pump

Figure 3 Connections on the pump

The following connections are available on the pump:

1. Inlet connecting flange

2. Outlet connecting flange

3. Electric connection (terminal box)

4. Venting

1.

2.

3.

4.

Auftrag-Nr.

Q

Bj./ Mon.

m

m /h

3

1

3

4

5

2

6

UNIBAD

Pumpe

Herborner Pumpenfabrik

J.H. Hoffmann GmbH & Co. KG

Littau 3-5, DE-35745 Herborn

7

Summary of Contents for UNIBAD-X

Page 4: ......