MODU-FIRE

®

Forced Draft Gas-Fired Boiler 2500-3000

33

5

MAINTENANCE

All weekly, monthly and annual maintenance checks should be performed by experienced and

knowledgeable personnel.

Installation and service must be performed by an experienced and knowledgeable

individual, such as a Harsco Industrial, Patterson-Kelley representative, qualified installer, service agency or

gas supplier.

Proper lockout /tagout procedures must be employed when servicing this unit.

A hazard analysis should be performed by the end user to insure the safety of their employees and/or service

technicians.

5.1 M

AINTENANCE AND

I

NSPECTION

S

CHEDULE

Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation.

Verify proper operation after servicing.

5.1.1 Daily

Observe operating temperature and general conditions. Make sure that the flow of combustion and ventilating air

to the boiler is not obstructed. Determine the cause of any illuminated red indicators, unusual noises or operating

conditions and make the necessary corrections.

Check daily to be sure that the boiler area is free and clear of any combustible

materials, including flammable vapors and liquids.

5.1.2 Weekly

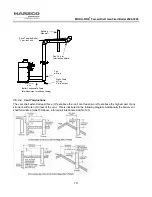

Observe the conditions of the main flame. A normal high fire flame shows an orange screen with a blue halo. In

Low fire the burner should display a reddish orange glow. However, do not attempt to adjust the flame “by eye”.

Correct air adjustment is essential for the efficient operation of this boiler. If an adjustment to the combustion is

necessary, the flue gas composition should be checked with a carbon dioxide (CO

2

) or oxygen (O

2

) analyzer to

set conditions. Refer to Section 3.12.

5.1.3 Monthly

1. Using the control panel, enter the information mode and scroll down to view the flame signal. When the boiler

is firing, the signal will be “yes” and when the boiler is not firing, the signal will be “no”.

2. Test high-limit control by reducing setting below the operating temperature. Burner should shut off. After

readjusting the thermostat, press the button to reset the switch.

3. Test operating temperature control by reducing temperature setting as necessary to check burner operation.

4. Check flue gas temperature at outlet. If there is a temperature increase over previous readings, the probable

cause is soot or water-scale build- up on the tubes.

Summary of Contents for 1004905923

Page 2: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 2 ...

Page 45: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 45 6 1 3 Wiring Schematic ...

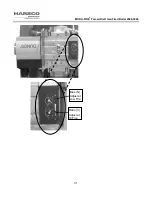

Page 48: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 48 6 1 6 Rear Junction Box ...

Page 49: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 49 6 1 7 Customer Connections ...

Page 56: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 56 ...