Summary of Contents for 1004905923

Page 2: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 2 ...

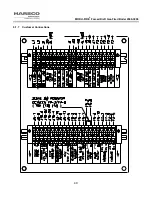

Page 45: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 45 6 1 3 Wiring Schematic ...

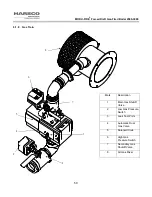

Page 48: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 48 6 1 6 Rear Junction Box ...

Page 49: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 49 6 1 7 Customer Connections ...

Page 56: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 56 ...