MODU-FIRE

®

Forced Draft Gas-Fired Boiler 2500-3000

38

5.6.3 Low

Gas

Pressure

The low gas pressure switch opens when there is insufficient gas pressure available for proper operation of the

boiler. LOW GAS PRESSURE is displayed, and burner operation is interrupted. If a gas-supply shut-off valve is

closed for any reason, a low gas condition will result. When gas pressure is restored, LOW GAS PRESSURE will

remain on the display panel. A manual reset is required to restart the boiler, provided that all other limits are

satisfied.

5.6.4

High Gas Pressure

The high gas pressure switch opens when there is excessive manifold gas pressure for the proper operation of

the boiler. HIGH GAS PRESSURE is displayed and the burner operation is interrupted. When proper gas

manifold pressure is restored, HIGH GAS PRESSURE remains on the display panel. A manual reset is required

to restart the boiler, provided that all other limits are satisfied.

5.6.5 High

Water

Temperature

When the boiler water has exceeded both the operating and high-limit temperature the high limit switch opens,

and HIGH LIMIT

is shown on the display. When the water temperature falls below the high-limit temperature, the

boiler will remain locked out until the water high limit switch is manually reset and the front panel reset button is

pressed. Once the switch and the control are reset, the sequence returns to Step 3 to await heat demand

provided that the other limits are satisfied.

5.6.6 Low

Air

The air switch has been factory set and should not be adjusted in the field.

If the display panel indicates AIR SWITCH NOT OPEN

or AIR SWITCH NOT CLOSE this indicates improper air-

flow through the boiler. Check the hoses leading to the air switches. Verify proper blower operation. An air switch

error does not necessarily mean that the air switch is defective.

When

AIR SWITCH NOT OPEN is shown on the display, check that the air switch is open when the fan is off.

Check that there is no air flow through the boiler when the fan is off.

When AIR SWITCH NOT CLOSE is shown on the display, check that the air switch is closed when the fan is

running. If the air switch does not close within 5 minutes during purge, the boiler locks out. Check that the burner

is clean and that there are no obstructions to airflow in the intake or exhaust ducts.

5.6.7

Vent Pressure

BLOCKED FLUE

indicates that the high exhaust back pressure switch has tripped. This may be caused by a

blocked stack, a blocked air inlet, or a blocked condensate system. When the blockage is removed, the boiler will

automatically restart.

5.6.8 Ignition

Failure

In the event the flame is not detected by the UV scanner during the 4 second trial-for-ignition period (Step 9), the

gas valve and spark ignition are de-energized. At this time a safety lockout occurs. A manual reset of the

programmer (located inside the control panel) is required.

5.6.9 Flame

Failure

In the event of a flame failure, the main fuel valves are de-energized and a manual reset lockout occurs. IGNI-

TION ERROR or FLAME ERROR is shown on the display. The cause of flame failure must be diagnosed and re-

paired before the control is reset.

When IGNITION ERROR is shown on the display, the boiler has not lit during a trial for ignition. Check that the

spark, electrode, ignition wire, and gas valve are functioning properly.

When FLAME ERROR is shown on the display, the boiler has lost the flame during run. Check that the combus-

tion is setup properly, the gas pressure is correct, as well as other combustion parameters.

Summary of Contents for 1004905923

Page 2: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 2 ...

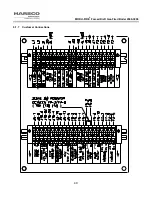

Page 45: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 45 6 1 3 Wiring Schematic ...

Page 48: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 48 6 1 6 Rear Junction Box ...

Page 49: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 49 6 1 7 Customer Connections ...

Page 56: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 56 ...