MODU-FIRE

®

Forced Draft Gas-Fired Boiler 2500-3000

34

5. Test the water flow switch by trying to restart boiler with the system pump off. The boiler should not operate

and the control should display LOW FLOW/ILK.

6. Test low gas pressure switch and high gas pressure switch utilizing the procedure in sections 3.11.4 & 3.11.5.

The boiler should fail to start and the control should display LOW GAS or HIGH GAS.

7. Inspect and clean the inlet screen of any accumulated dust or lint.

8. The relief valve should be tested as per manufacturer’s instructions or every two months by lifting the lever for

5 seconds and allowing the valve to snap shut. Please see the manufacturer’s recommendations on the relief

valve tag.

5.1.4 Annually

In addition to the recommended monthly service:

1. Check burner and wash off (do not scrub or use wire brush) any soot or foreign material that may have

accumulated. See Section 5.2 on "Cleaning the Burner." Check the burner and its parts. If there is evidence

of deterioration or corrosion, replace immediately.

2. Inspect combustion chamber. To access the heat exchanger, remove the front door and the front inner

wrapper. Note any signs of deterioration. Examine the gasket and replace if necessary, using a Harsco

Industrial, Patterson-Kelley gasket kit only.

3. Inspect and clean heat exchanger. Wash the copper tubes with water and non corrosive soap. Green scale

on the tubes indicates that the boiler is condensing which is detrimental to boiler life. Perform corrective action

as necessary.

4. Examine the venting system.

a. Check all joints and pipe connections for tightness.

b. Check vent for corrosion or deterioration. If any venting needs replacing, do so immediately.

5. Inspect heating system for other problems.

6. Perform combustion analysis and adjust if necessary (See 3.14.1).

7. Leak test gas valves. Leak Test must be performed only by qualified Harsco Industrial, Patterson-Kelley

certified personnel, who have been trained in this procedure. This procedure is available on request from the

Harsco Industrial, Patterson-Kelley Factory.

8. Perform a safety relief valve test.

Summary of Contents for 1004905923

Page 2: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 2 ...

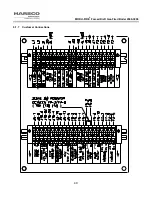

Page 45: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 45 6 1 3 Wiring Schematic ...

Page 48: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 48 6 1 6 Rear Junction Box ...

Page 49: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 49 6 1 7 Customer Connections ...

Page 56: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 56 ...