4 - Sprayer setup

32

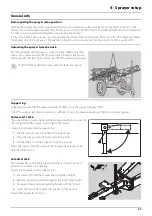

Hydraulic systems

General info

Ensure that the snap couplers are clean before connection!

After having operated the boom and the system has been filled with oil, check the tractor’s hydraulic oil level and top up, if

necessary.

€

DANGER! Test of the hydraulic system should be done very cautiously. There may be air trapped in the system which

can cause violent movements of the boom.

€

DANGER! Hydraulic leaks: Never use your fingers to locate a leakage in any part of the hydraulic system. Due to high

pressure, hydraulic oil may penetrate the skin.

Requirements - tractor (SPB/SPC model)

Y-model requirements

•

One single acting outlet for the lift function of the spray boom.

•

One double acting outlet for the folding function.

Z-model requirements

•

One double acting outlet for the electro-hydraulic operation of the boom functions.

General

Ensure that snap couplers are clean before connection!

The hydraulic system requires a minimum oil pressure of 130 bar, max. oil pressure of 210 bar and an oil capacity of approx.

25 litres.

±

WARNING! Due to the variation in tractor hydraulic systems and capacities, care should be exercised when initially

operating the sprayer hydraulic cylinders. It is advisable to adjust the hydraulic flow control down to the minimum

rate before operating the system. Adjust/increase the flow control after the system is bled of any air, if necessary.

μ

ATTENTION! After having operated the boom and the system has been filled with oil, then check tractor’s hydraulic

oil level and top up if necessary.

Summary of Contents for RANGER EAGLE

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 26: ...3 Description 26 ...

Page 40: ...4 Sprayer setup 40 ...

Page 60: ...5 Operation 60 ...

Page 84: ...6 Maintenance 84 ...

Page 95: ...8 Technical specifications 95 Charts Boom hydraulic Z Boom hydraulic Y ...

Page 96: ...8 Technical specifications 96 ...

Page 100: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...