93

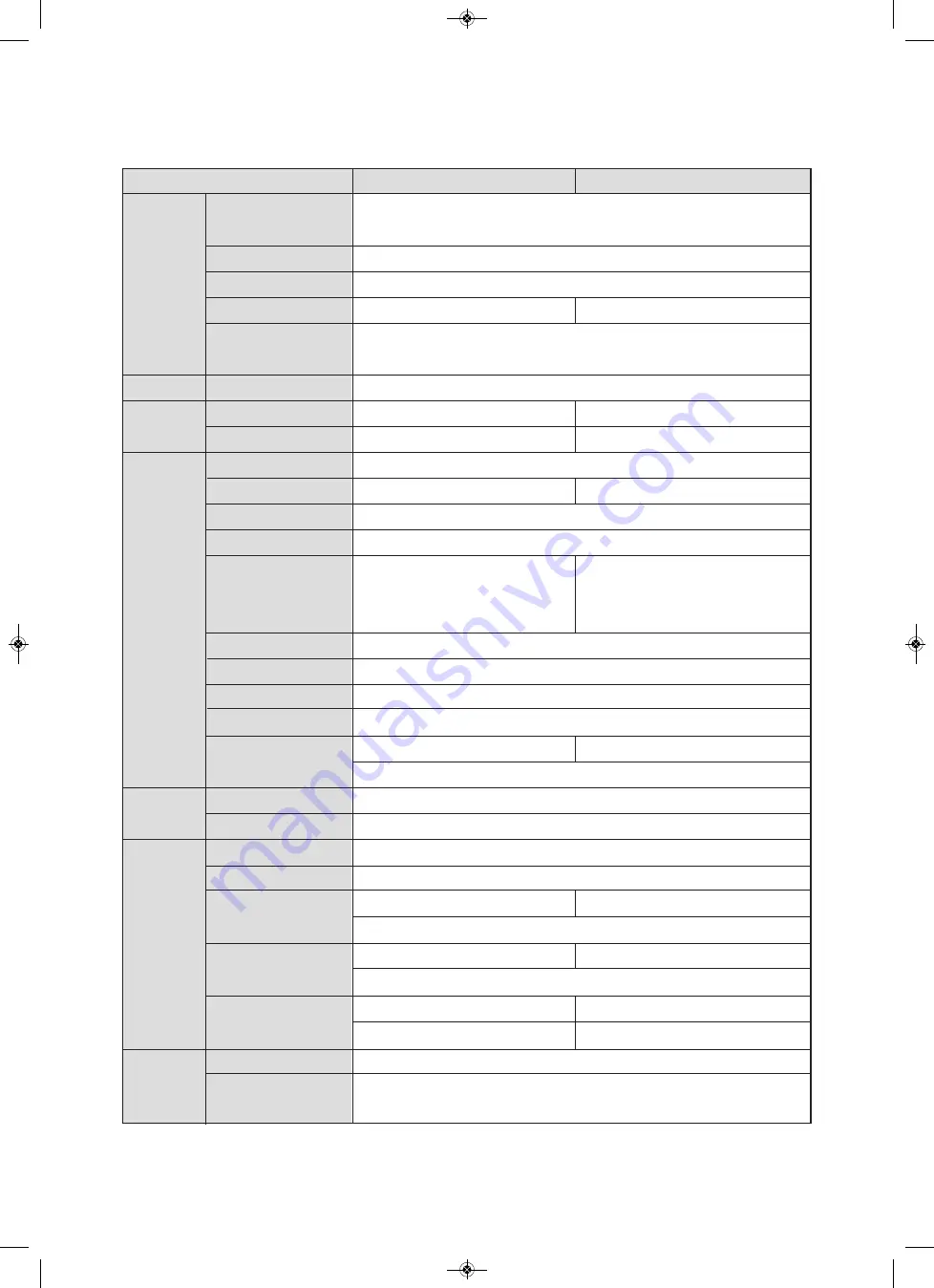

Bias(Deviation)

Dry· Wet sensor Bias

Scaling

LPF

Detection of sensor

disconnection

Operation method selection

Temperature

Humidity

Pattern

Segment

P.I.D group

Auto Tuning

Proportional

Band

Integral Time

Derivative Time

ON/OFF control

Direct/Reverse action

ON/OFF

Hysteresis

Temp•Humidity

Scaling

Setting Alarm

Alarm type

Process Alarm

Deviation Alarm

Hysteresis

Memory

Memory function

Input

Control mode

Control

output

Control

Action

Retransmission

Output

Alarm

Setting

Storage

against Power

failure

Temp. : -100.00 ~ 100.00 (℃)

Humidity : -100.0 ~ 100.0 (% R.H)

After removing gauze from wet sensor, correct the difference between dry and wet sensor.

V d.c : Input scale in accordance with conversion range

2 ~ 180 sec

1 ~ 180 sec

Up scale(In case of R.T.D input),

Stop operation when it is over ±5 % of its range

Fix Control / Program Control

SSR/SCR 4 - 20 ㎃ d.c

SSR (Pulse Voltage)

SSR/SCR 4 - 20 ㎃ d.c

SSR (Pulse Voltage)

100 patterns (1 pattern/100 segments)

6,000 max segments

2,000 max segments

16 Groups (Temp 4 zones x Humidity 4 zones)

Auto Tuning according to SV(Setting Value)

Temp. : 0.00 ~ 600.00 ℃

Humidity : 0.00 ~ 200.00 %

0.00% = ON/OFF control

0.0 ~ 6.000 sec ( 0 sec = OFF )

0.0 ~ 6.000 sec ( 0 sec = OFF )

Set the Proportional Band as 0.0

Select Direct or Reverse action in control output.

0.1 ~ 300 ℃ 0.1 ~ 600.0 ℃

(In case of humidity, it is a web bulb temperature or converted value)

4 - 20 ㎃ d.c, Select among PV,SV and MV(Manipulated Value)

Perform scaling of the High· Low deviation range 4 - 20 ㎃ d.c automatically

System Alarm : 4 points Alarm per pattern : 4 points

Including HighoLow /Low deviation alarm etc. 20 types of alarm are available.

Temp. : -100.0 ~ 200.0 ℃

Temp. : -100.0 ~ 500.0 ℃

Humidity : 0.0 ~ 100.0 % RH

Temp. : -300.0 ~ 300.0 ℃

Temp. : -600.0 ~ 600.0 ℃

Humidity : 0.0 ~ 100.0 % RH

Temp. : 0.0 ~ 300.0 ℃

Temp. : 0.0 ~ 600.0 ℃

Humidity : 0.0 ~ 100.0 % RH

Humidity : 0.0 ~ 100.0 % RH

Internal Flash Memory and FRAM

Program Information and SV(Setting Value) backup and restoration.

Storage of Temperature-Humidity setting value and PV

8.5 Functions

Model

TH500

TH300

0.00 ~ 100.00 %

0.00% = ON/OFF control

th300_500_통합본_th300_500_통합본.qxp 19. 6. 26. 오후 1:36 페이지 93