9

APM-001e

AUG 2015

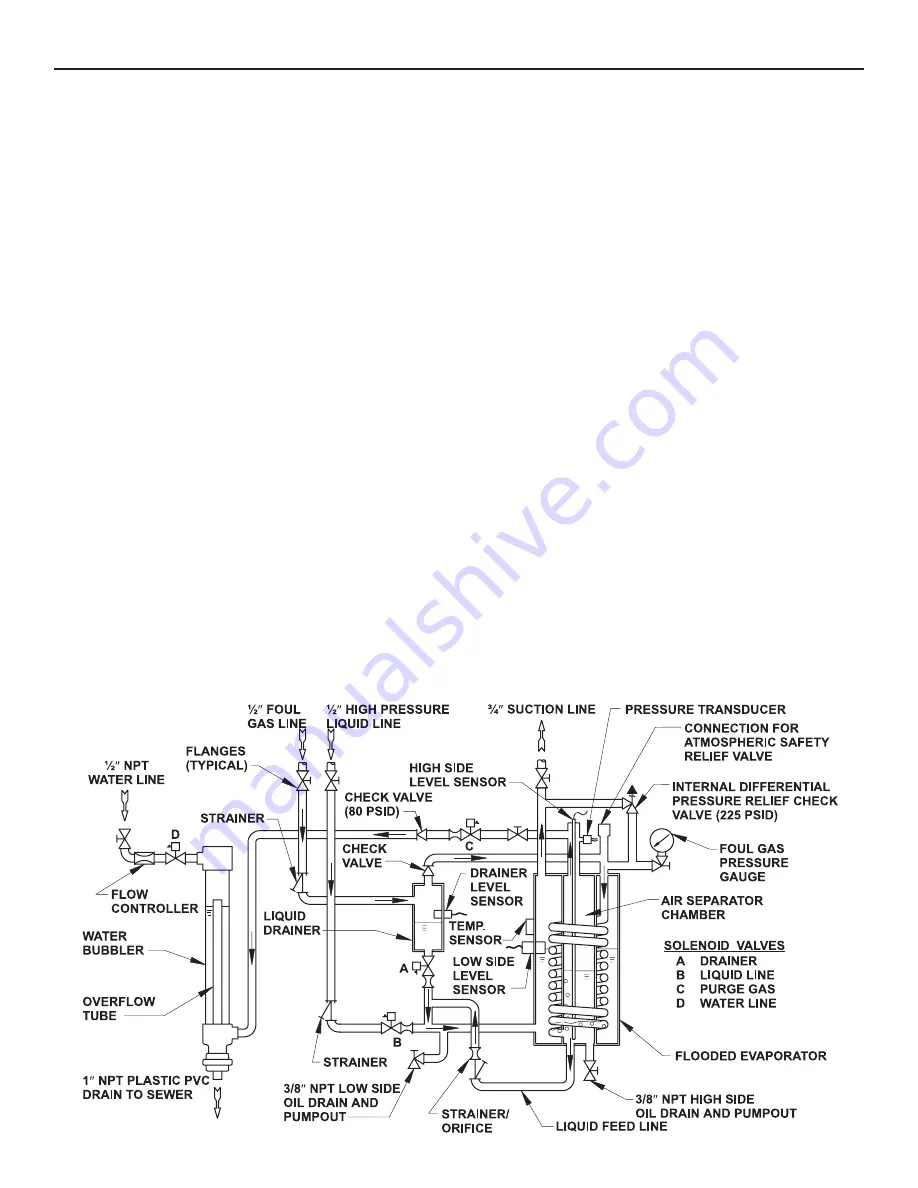

The APM is designed to automatically start-up and operate

without the assistance of plant personnel. Beginning at

start-up, the following is a description of the refrigerant

flow through a purger.

Keep the control cabinet door closed at all times to

prevent water damage and tampering.

PURGER START-UP SEQUENCE

On start-up, liquid refrigerant fills and begins to cool the

purger. The liquid line solenoid valve (B) energizes to

feed refrigerant to the flooded evaporator. The low side

level sensor, located on the side of the flooded evaporator,

senses when liquid reaches the proper level. The display

should show 3333.

At the same time the flooded evaporator is filling, foul

gas enters the flooded evaporator condensing coil and

the refrigerant gas contained therein changes state to a

liquid. The liquid and noncondensible gas gradually fill

the air separator chamber.

As the purger continues to cool down, a temperature sensor

attached to the flooded evaporator senses temperature.

At approximately 40°F (4.4°C) evaporator temperature, the

readout will no longer display 3333 and the purger will

enter the mode selected.

Foul gas is continually processed as long as a remote

purge point solenoid is energized. It is important that

one, but only one, remote purge point solenoid valve is

open at all times to prevent losing foul gas pressure to the

purger. If foul gas pressure is lost (as sensed by pressure

transducer), diagnostic code 2222 flashes on the APM

digital readout. No purging of air will occur until foul gas

pressure is restored.

OPERATION

The foul gas may carry a certain amount of condensed

refrigerant which is captured by the liquid drainer before

it enters the flooded evaporator coil of the purger. The

drainer level sensor operates solenoid valve (A) to drain

the liquid directly into the low-pressure flooded evaporator.

This separation step enables the liquid refrigerant to bypass

the purger’s flooded evaporator condensing coil.

The liquid-free foul gas enters the condensing coil, which

is submerged in the cold liquid refrigerant of the flooded

evaporator. The refrigerant gas condenses while the

noncondensible gas passes into the air separator chamber.

The condensed liquid refrigerant is removed from the air

separator chamber through the strainer with integral orifice,

and passed into the low-pressure side of the flooded

evaporator.

Meanwhile, the noncondensible gas collects in the air

separator chamber. The collected noncondensible gas

gradually depresses the liquid level causing the high side

level sensor to open both the purge gas solenoid valve

(C) and water solenoid valve (D). Inside the water bubbler,

noncondensible gas and water mix so that residual amounts

of ammonia can be absorbed. The waste water is flushed

to the drain through the overflow tube.

The purger will cycle each enabled remote purge point

solenoid valve in sequence, when the purger is on Automatic

Operation or New System Start-up. The Purger will remain

at the selected purge point when in Manual Operation.

SECTION 3 APM OPERATION

Figure 11