7

APM-001e

AUG 2015

ACTIVE PURGE POINT

The front of the control cabinet has lights which indicate

the active purge point. The active purge point can be

manually advanced in any operational mode by pushing

the purge point advance button.

PURGER STATUS LIGHTS

There are two purger status lights on the front of the control

cabinet next to the digital readout. These are the Purging

status light and Standby status light which indicate when

noncondensible gas (air) is being released from the purger

(Purging), or when the purger is in a waiting mode (Standby).

PURGING LOG

The purging log is displayed on the digital readout. It

displays the number of minutes the purge gas solenoid valve

(C) (see Figure 11) has been open to release noncondensibles

into the water bubbler.

The purger log can be used to track the release of

noncondensible gas. If a daily or weekly record is kept, then

any abnormal increases in the amount of noncondensible

gases can be noted, and corrective measures can be taken.

Little or no activity compared to normal operation may

indicate noncondensibles have been thoroughly removed

or a problem with the purger. Frequent activity beyond

normal could mean excessive new leakage of air into the

system. To reset the purge log, push the zero reset button

next to the digital readout on the front panel.

DIAGNOSTIC FEATURES

Although the APM is very reliable, after an extended

operation or under severe conditions, problems may

occur or be suspected. Under these conditions, due to

the importance of the purging functions, restoration to

normal operation is desired as quickly as possible. The

APM features diagnostic codes which are displayed on the

digital readout when abnormal operation of the refrigeration

system or the APM is detected. These flashing numbers

help to identify the problem area. Below is a quick reference

to these diagnostic codes. The digital readout will display

the diagnostic code related to the occurrence which first

put the APM into this mode; exception, 6666 will override

7777. Also see the troubleshooting guide on page 10 for

detailed explanation.

Flashing 2222 LOSS OF FOUL GAS PRESSURE.

Flashing 3333 PURGER TOO WARM.

Flashing 4444 PURGED OVER 60 MINUTE TIME LIMIT.

Flashing 5555 PURGER SHUT-OFF REMOTELY.

Flashing 6666 LEVEL CONTROL OUT OF RANGE.

Flashing 7777 LOSS OF HIGH-PRESSURE LIQUID.

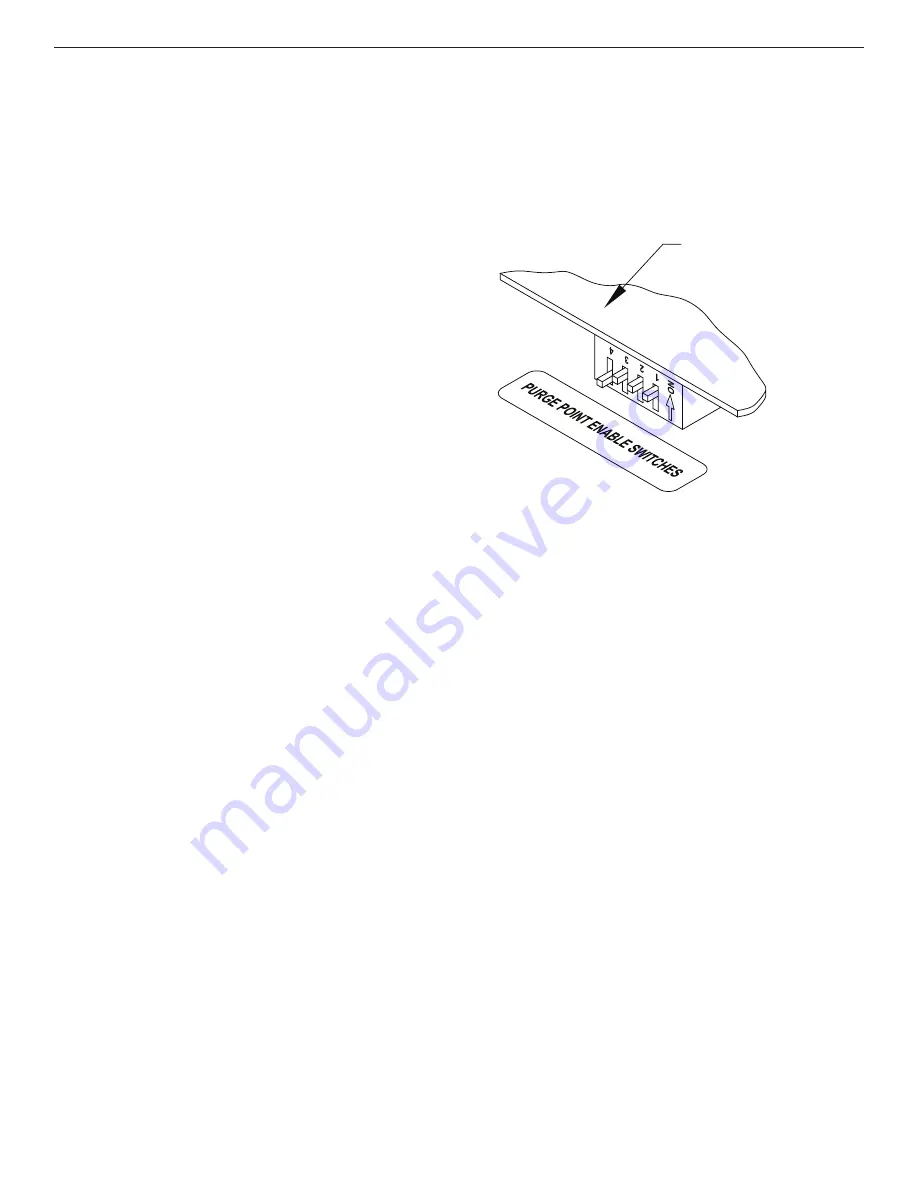

PURGE POINT ENABLE SWITCHES

These switches are located on the control board and are

all factory-set to the ON position. They control whether

or not a purge point can become active. If for example,

only three purge points are being utilized, the number 4

purge point enable switch should be in the downward off

position (see Figure 7). By doing this, the unused purge

point is disabled and purger time is not wasted.

PUMP OUT PROCEDURE

Performing certain types of service on the APM may first

require the purger to be pumped-out (drained of liquid

refrigerant). To begin pump-out, shut off the foul gas

and high-pressure liquid lines. Wait for all refrigerant to

evaporate to suction; this usually takes several hours to

complete. Using safe refrigeration practices, reduce the

pressure to zero. In addition to following these procedures,

check the lower portion of drainer and the APM piping for

signs of frost. If there is no frost, pump-out is probably

complete. If there is frost, this means excess refrigerant

is still in the drainer and/or piping. To drain, energize the

drainer solenoid valve.

To accelerate the pump out process, attach ammonia hoses

to the oil drain valves. Close the main suction line to the

purger. Using the oil drain valves, pump out to a lower

suction pressure than the main purger suction line. When

pumped out, close the oil drain valves and leave the main

suction line closed to isolate the purger. With electricity

on, the pressure in the purger should remain at zero. This

process should be completed only by knowledgeable

refrigeration technicians.

CONTROL BOARD

Figure 7

SECTION 2 ELECTRICAL INSTALLATION & OPERATION