8

APM-001e

AUG 2015

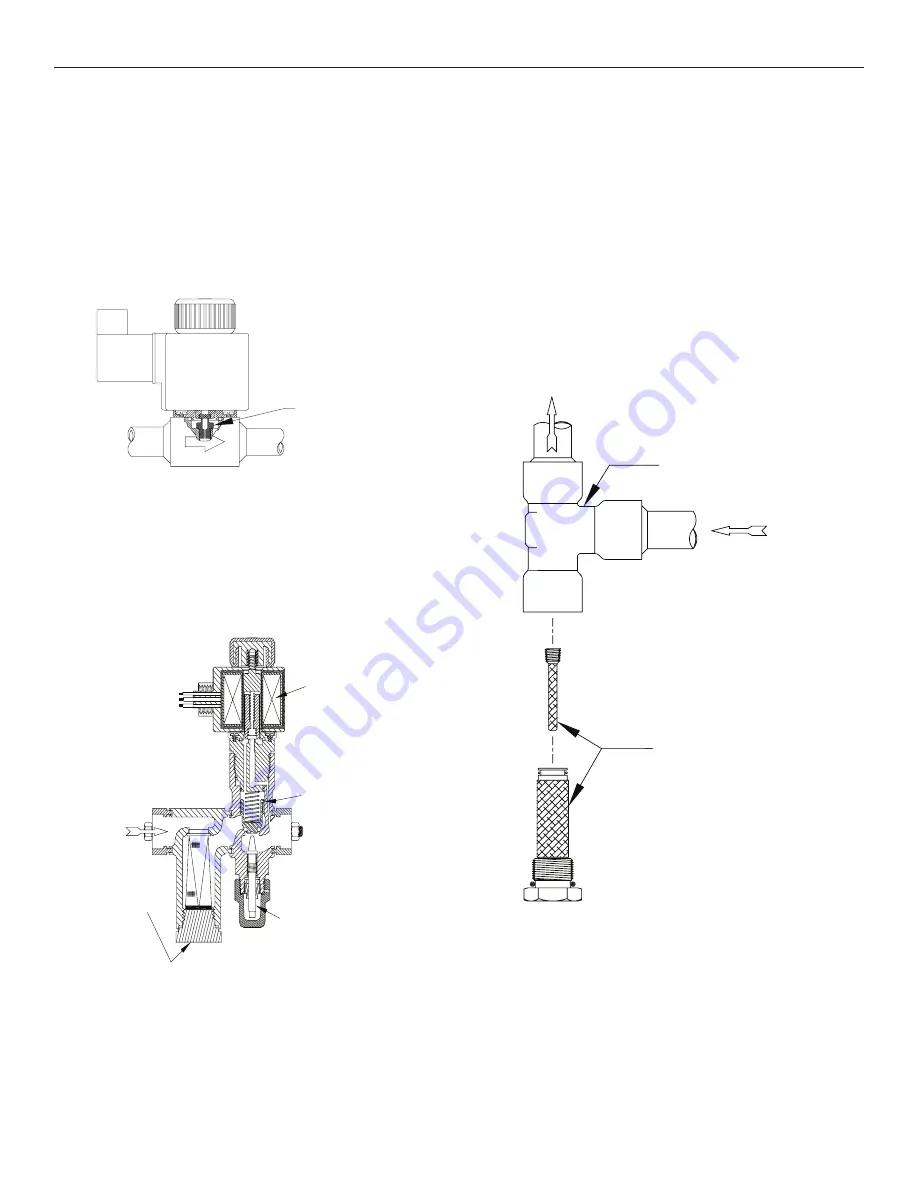

SOLENOID VALVES

The APM is equipped with four solenoid valves. These are:

the liquid drainer solenoid valve (A), the liquid line solenoid

valve (B), the purge gas solenoid valve (C), and the water

solenoid valve (D). See Figure 11. With the exception of the

water solenoid valve, each is directly welded in-line and

has a stainless steel removable seat/orifice (see Figure 8).

The removable seat/orifice facilitates easy access to the

orifice for inspection or replacement. If necessary, the

water solenoid valve (D), whose brass body has threaded

ends, can easily be replaced or parts thereof changed.

Figure 8

LIQUID DRAINER

The liquid drainer removes any condensed liquid that trickles

from the foul gas line into the purger. This enables the

purger to always be condensing gas, rather than having

liquid entering the condensing section of the purger and

limiting proper operation. The drainer solenoid valve (A)

will open to empty a reasonable amount of excess liquid

directly to the flooded evaporator. However, if too much

liquid comes down the foul gas line, due to improperly

piped condensers, corrective action must be taken. See

the Foul gas piping section on page 3.

STRAINER/ORIFICE

The strainer/orifice meters condensed liquid refrigerant

from the high-pressure side of the purger into its flooded

evaporator. It features a dual filter arrangement to reduce

potential orifice blockage. This dual filter (strainer) removes

particles and houses the integral orifice (strainer/orifice

screen assembly). See Figure 10.

In addition, separate remote point solenoid valves are

required, one for each enabled purge point. These are not

included with the APM. The Hansen type HS8 solenoid

valve having a ½” (13mm) port and a stainless steel piston

is recommended. Below is a typical purge point solenoid

valve with close-coupled strainer (Figure 9).

Figure 9

REMOVABLE

SEAT/ORIFICE

CHECK VALVES

There are three check valves on the purger. An 80 psid

(5.5 bar) differential check valve is installed on the purge

gas line to prevent any possibility of reverse flow of water

into the purger. A 225 psid (15.5 bar) differential relief

check valve leads from the condensing coil inlet to the

suction line; this prevents excessive purger pressure. A

third check valve is installed from the liquid drainer to the

evaporator coil to prevent reverse flow with a temporary

loss of foul gas pressure.

WATERTIGHT

ENCAPSULATED

COIL

STAINLESS

STEEL PISTON

MANUAL OPENING

STEM

CLOSE-COUPLED

STRAINTER

REMOVABLE SEAT

ORIFICE

WATER BUBBLER

The APM is equipped with a water bubbler which eliminates

any water bottle attention. Purge gas (noncondensibles)

from the purger flows into the bottom of the water bubbler

where residual ammonia can be absorbed into the water.

The water with absorbed ammonia flows to a drain. The

water solenoid valve (D) opens to automatically replenish

water to the bubbler each time the purge gas solenoid

valve (C) energizes. A 30-second delay keeps the water

solenoid valve (D) open after the purge gas solenoid valve

(C) de-energizes to refill water bubbler. Proper release of

noncondensibles through the bubbler is usually indicated

by large, 1/2" (13mm) diameter bubbles.

STRAINER/ORIFICE

SCREEN ASSEMBLY

STRAINER/ORIFICE

BODY

STRAINER/ORIFICE

BODY

STRAINER/ORIFICE

SCREEN ASSEMBLY

SECTION 2 ELECTRICAL INSTALLATION & OPERATION

Figure 10