Operating instructions

Keep this manual to hand and in good condition for future reference!

Please read this operating manual carefully before using the machine!

Translation of the original operating instructions

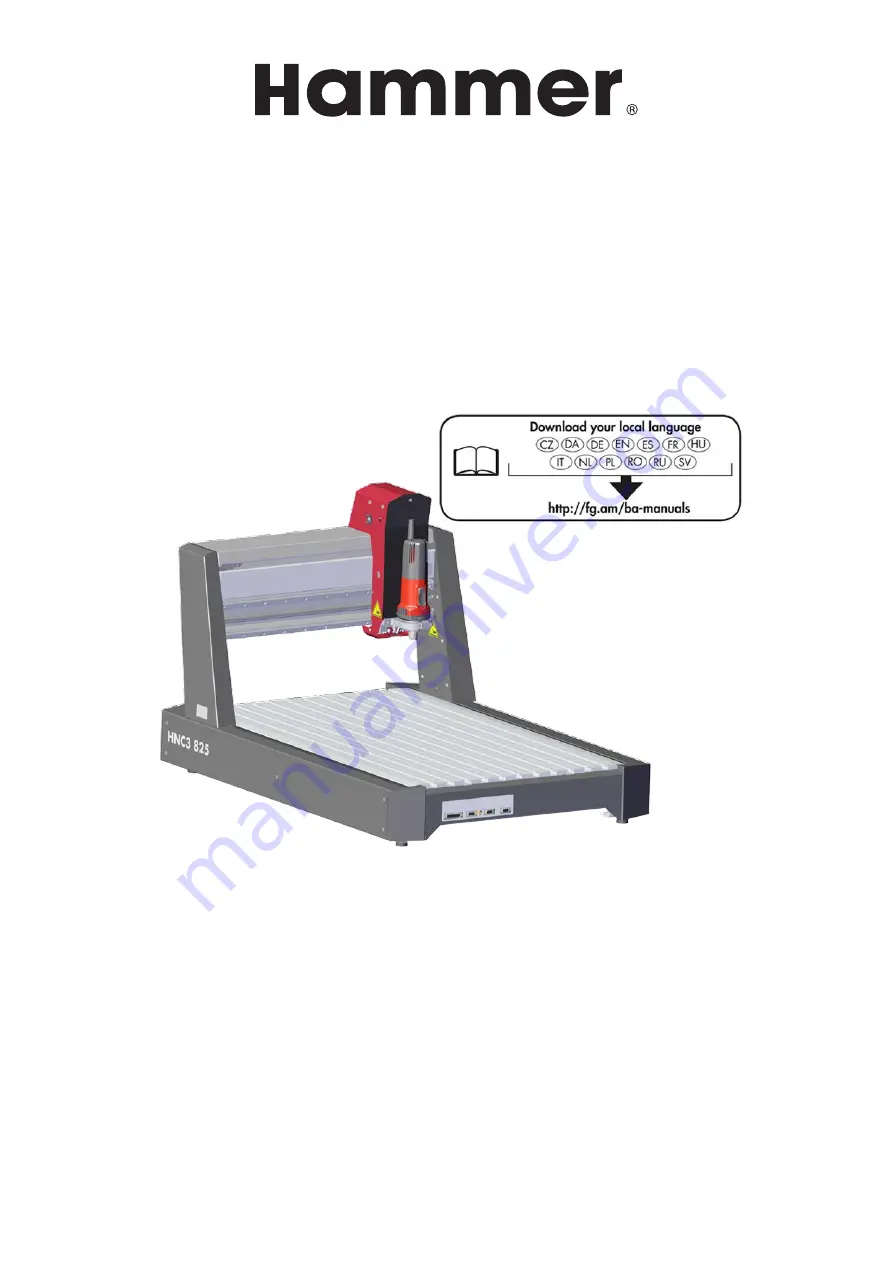

HNC3 825 /

HNC3 825 perform

CNC Machining Centre

500034-900A, 5, en_GB