7

5. Operation

Heated solder and flux can cause oxides to form and adhere to the nozzle and the

inside of the heating element. These oxides not only lower the heat conductivity, but

can also clog the nozzle and heating element, resulting in a drop in suction efficiency.

Should there be a noticeable drop in suction efficiency during operation, replace the

filter and clean the nozzle and heating element with the provided cleaning pin.

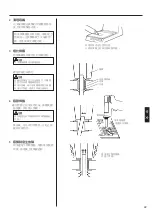

Cleaning during Operation

1. Observing the indicator

While looking at the indicator and

with the hole of the nozzle open,

pull the trigger and look at the in-

dicator. If it is red, clean the nozzle

and heating element, empty the

filter pipe, and replace the filters. If

the indicator is blue, cleaning is not

necessary and operations can be

resumed.

CAUTION

The indicator will not operate accurately if

the hole of the nozzle is closed or if the sol-

der in the hole of the P.W.B. is not melted.

CAUTION

The indicator on the HAKKO 475 reads

in a different way.

For instruction on the reading the

HAKKO 475 indicator, please refer to

the HAKKO 475 instruction manual.

2. Replacing the filter

Replace the filter as shown 1 to 3.

During operation, the filter pipe is

very hot. Wait until the filter pipe is

cool before replacing the filter.

We recommend keeping a second

filter pipe containing new filters han-

dy, and replacing the installed filter

pipe with this backup filter pipe.

3 Replace the entire filter pipe

with he provided backup filter pipe.

2 Pull

1 Down

Normal

Blue or slight

amount of red

can be seen.

Abnormal

More than half

of the indicator

is red.

Solution

If the indicator is more than

half red, replace the filter

and clean the nozzle and

the inside of the heating

element.

(refer to p.12 Maintenance

of the Desoldering Gun)

CAUTION : If there is a noticeable drop in suction

efficiency, clean the nozzle and heating ele-

ment with the cleaning pin.

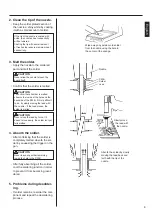

Problems during Desoldering

A. The solder in the junction is

not sufficiently melted.

B. Suction power is dropping.

A. The solder in the junction is not sufficiently melted.

l

Temperature is not high enough

The following parts require a greater heat capacity to desolder.

• Multilayer P.W.B.s, power supplies, ground planes in through-hole

P.W.B.s, high-capacity transistors, triacs with heat radiation fins, tuner

P.W.B. ground wires, and large-scale transformer terminals.

Use a preheating oven or heating gun to heat the P.W.B. to a temperature that

won’t damage the board or its components [between 70°C (160°F) and 80°C (180

°F)], then desolder. Do not increase the temperature of the gun by recalibration

as this may damage the P.W.B. and its components.

l

Nozzle is worn out.

• When the nozzle begins to wear out, the heating efficiency begins

to decline. Check the nozzle. If the solder plating is damaged, or the

nozzle is eroded, replace the nozzle. (refer to p.9)

English

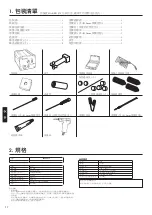

Summary of Contents for 474

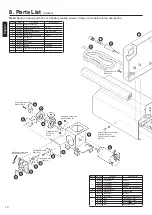

Page 19: ...3 18 1 2 M4 25 380 480 HAKKO...

Page 21: ...20 5 B1094 B1095 HAKKO 474 1 M4 25 2 3 4 IRON VACUUM...

Page 22: ...21 1 2 1 2 5 6 3 5 3 1 HAKKO 191 HAKKO 192 HAKKO 474 380 480 1 2 3 4 5 6...

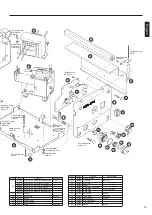

Page 23: ...22 2 3 4 5...

Page 24: ...23 1 HAKKO 475 HAKKO 475 HAKKO 475 2 1 3 3 2 1 A B A 70 80 25 25 5 25...

Page 25: ...24 HAKKO 474 B 25_26 20 25 26 24 20 28 a b c d e f...

Page 26: ...6 25 HAKKO 474 1 2 3...

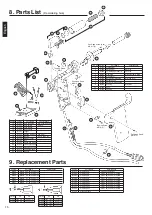

Page 27: ...26 6 A1033 A1033 4 A1033 5...

Page 28: ...27 1 A1009 2 1 2 3 A1009 S20 6 VACUUM...

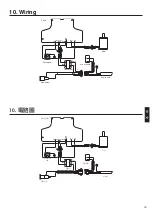

Page 29: ...28 7 23 2 4 1 2 3 4 24V 50W 5 1 3 CAL 380 CAL...