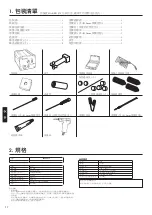

11

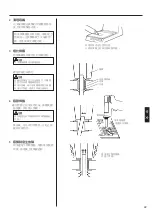

6. Maintenance

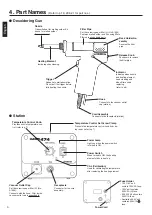

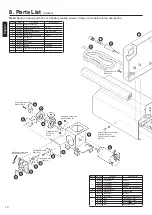

(Station)

Cleaning the inside of the Filter Case

Cleaning the Pump

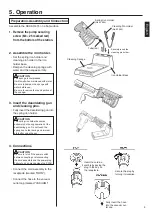

WARNING

Unplug the power cord before starting this

procedure.

1. Disassemble the pump heads.

• Remove the rear panel.

• Remove the cover.

• Remove the pump head from each

side of the pump.

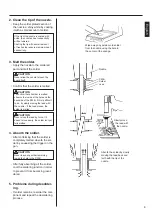

2. Clean the pump head.

• Remove the valve plate and fixing

plate.

• Remove any flux adhering to the

plates.

CAUTION

If the fixing plate is difficult to remove,

apply hot air to it to warm it up.

Never use excessive force to remove the

plate as it is easy to bend, and a bent

plate will allow air to leak out and reduce

solder vacuuming efficiency.

CAUTION

Clean the plates only with alcohol or thinner.

Replace

If the valve plate is bent or stiff, replace it.

• If the exhaust filter is dirty, replace

it.

3. Assemble the pump heads.

Reassemble the valve plate and

fixing plate.

CAUTION

When assembling the pump, be sure to

check for air leaks.

VACUUM

Ceramic Paper

Filter (S)

(No.A1009)

Filter Retainer

Remove the filter retainer

and push out the ceramic

paper filter.

Cover

Rear Panel

Remove

the screws

Remove

the cover screws.

(right/left)

Clean the pump head

and fixing plate.

Fixing Plate

Valve Plate

Pump Head

Exhaust Filter

Pump Head

Valve Plate

Be sure the parts are

aligned correctly.

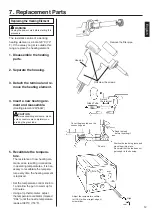

1. Replace the ceramic paper

filter (No.A1009).

Remove the ceramic paper filter

and inspect it. If it is stiff with flux,

replace it.

2. Reassemble the filter case.

CAUTION

Set the ceramic paper filter (S) for the

filter retainer (station).

Using the ceramic paper filter (L) in the

filter retainer may cause to break or the

power to drop.

Secure the vacuum outlet cap.

Apply silicone grease to the O-ring (S20) and securely

tighten the vacuum outlet cap to prevent air leakage.

Fixing Plate

English

Summary of Contents for 474

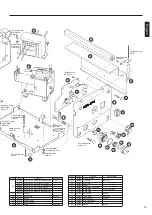

Page 19: ...3 18 1 2 M4 25 380 480 HAKKO...

Page 21: ...20 5 B1094 B1095 HAKKO 474 1 M4 25 2 3 4 IRON VACUUM...

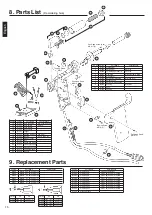

Page 22: ...21 1 2 1 2 5 6 3 5 3 1 HAKKO 191 HAKKO 192 HAKKO 474 380 480 1 2 3 4 5 6...

Page 23: ...22 2 3 4 5...

Page 24: ...23 1 HAKKO 475 HAKKO 475 HAKKO 475 2 1 3 3 2 1 A B A 70 80 25 25 5 25...

Page 25: ...24 HAKKO 474 B 25_26 20 25 26 24 20 28 a b c d e f...

Page 26: ...6 25 HAKKO 474 1 2 3...

Page 27: ...26 6 A1033 A1033 4 A1033 5...

Page 28: ...27 1 A1009 2 1 2 3 A1009 S20 6 VACUUM...

Page 29: ...28 7 23 2 4 1 2 3 4 24V 50W 5 1 3 CAL 380 CAL...