3

CAUTION

No unit is allowed to be installed near such places that are dirty, oily, salty, exposed to a large amount of

sulfur gas and where the unit parts may be subjected to corrosion, such as toilet vent, operation room

vent and sewage treatment equipment.

If the unit is operated below 0

℃

, it must be installed at a place at least 300 mm above the ground, so as

to avoid icing of unit base plate and to ensure the normal operation of the unit even though the snow

reaches this height; in addition, the unit shall be placed on a plane (with maximum deviation per meter of

not more than 2 mm).

It is forbidden to change the setting value of the safety protection device. Failure to do so may result in

fire, explosion, etc.

If the wire harness wiring sequence is connected incorrectly, component and controller damage will

occur. Please check the cable sequence before powering on to avoid controller damage.

The unit must be warmed up for two hours for the first time. This is to protect the compressor. If the

preheating time is not met, the unit may report the oil preheating and the temperature barrier.

If the unit is running below 0 °C, it must be installed at least 300mm above the ground. This is to avoid

the unit chassis freezing, and to avoid the normal operation of the unit due to the thickness of the snow

reaching this height. It should be installed on a flat surface (maximum deviation should not exceed 2mm

per meter).

Prepare protective equipment and installation tools. Protective equipment, including gloves, work

clothes, etc., can prevent accidental personal injury.

It is forbidden to use fuses that exceed normal capacity. Replacing a fuse with a wire or the like will be a

safety hazard or cause a fire.

It is forbidden to short-circuit the safety device and force the unit to start. This can result in damage to

the unit, fire, explosions, etc.

It is forbidden to use other uses beyond the scope of its unit design. This machine is not suitable for

storing food, animals, plants, art, etc., otherwise the quality of these items will be degraded.

Before the unit is repaired and maintained, the unit must be stopped and the power supply must be cut

off. Otherwise, there will be consequences such as electric shock and accidental injury.

When the unit is deactivated for a long time, the residual water inside the unit must be exhausted. If the

unit is out of service for a long time, the water pipe should be filled with preservatives or the remaining

water in the pipe should be removed. Otherwise, the unit components may be cracked and leaked.

Do not place or hang any objects above the unit. Accidental injury can occur when an object is dumped

or dropped.

It is forbidden to operate the unit with wet hands. Otherwise it will cause an electric shock.

Do not touch the unit fan and other moving parts. Failure to do so may result in accidental injury.

If the unit is running abnormally, you must cut off the power immediately and get in touch with the dealer.

■

Precautions for using R410A refrigerant

The system must be filled with liquid refrigerant. If a gaseous refrigerant is used to fill the system, the

refrigerant composition in the system will change and the performance of the unit may decrease.

Summary of Contents for CA0065EANR

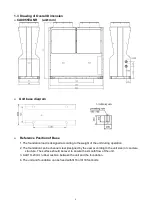

Page 8: ...5 1 2 Main components of the unit ...

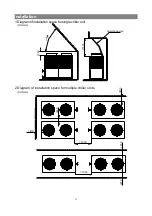

Page 15: ...12 Installation 3 Diagram of arrangement of multiple chiller units Unit mm ...

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......