10

Installation

Pre-installation Preparation

◆

Cargo inspection

All units are firmly bolted on wood trays, subject to ex-factory inspection and filled with accurate amount

of R410a refrigerant and refrigeration oil for the unit operation. Upon the receipt, you shall carefully

inspect cargoes for any damage during transport and confirm all ordered parts and accessories are

delivered.

You shall inform delivery man of any damage immediately. And you shall inform problem to us other than

appearance damage immediately.

◆

Handling

You shall handle the unit by a forklift or crane. If a

crane is used, the top and side panel of the unit

shall be protected by appropriate spacers (as

shown in the figure). During the handling, the unit

shall be kept horizontal and not be inclined for

more than 30°, and the unit damage due to

violations shall be avoided.

◆

Disassembly

Place the unit at a desired position, cut binding

tapes, remove the external crate, unscrew bolts

and remove the wood base from the unit bottom.

■

Selection Installation Position

For the better cooling (heating), the installation position of the chiller unit shall be selected as per the

followings:

◆

The unit shall be installed at a place where the hot air exhausted by the unit is not sucked back, that

exhausted by other unit is not sucked and sufficient space is reserved for the unit maintenance.

◆

Exhaust and suction channels of the chiller unit shall be free of any barrier that will block the air flow.

◆

The unit is installed at a well ventilated place to improve the heat exchange.

◆

The installation position shall have enough strength to withstand the unit weight and the vibration

during operation.

◆

The unit shall not be installed at a place that is dirty, oily, salty and exposed to a large amount of

sulfur gas.

◆

The chiller unit shall not be installed at such place where flammable gas may leak. Because the

flammable gas leaked and accumulated around the unit may lead to explosion.

◆

The chiller unit shall not be installed at such a place exposed to strong wind or typhoon or

accumulated rainwater and snow. If possible, auxiliary equipment for preventing rainwater, snow

and direct sunshine may be provided.

◆

The unit base shall be made of concrete or support. Full consideration must be given to floor

strength, drainage (water is drained from the unit during operation) and pipe and wire route in the

base construction. If the base is not strong enough, the unit may fall down, causing unit damage or

personal injury.

◆

The chiller unit shall be firmly fastened with anchor bolts to prevent falling down due to earthquake

or strong wind. In order to withstand strong wind and earthquake, the unit must be positioned

properly and can not be installed at such a place exposed to strong wind.

◆

Depending on installation conditions, vibration may be transferred to fitted parts, and base plates

and walls may produce vibration and noise. Therefore, proper vibration protections (e.g. setting

shock pad, dumper bracket, etc.) shall be provided.

◆

Edges and corners must be positioned correctly. The improper installation may lead to instability,

resulting in bending of mounting feet. Any improper installation may cause the falling down of the

unit, leading to personal injury.

Summary of Contents for CA0065EANR

Page 8: ...5 1 2 Main components of the unit ...

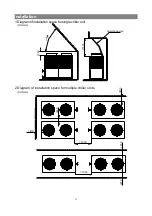

Page 15: ...12 Installation 3 Diagram of arrangement of multiple chiller units Unit mm ...

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......