25

Repair and maintenance

6.1 Regular inspection of the project

Before delivery, the unit has been rigorously tested and inspected to ensure that the product has good

performance after leaving the factory. In order to ensure long-term good operation of the unit, the user

should carry out regular maintenance and maintenance.

1. Condenser inspection and cleaning

In order to ensure the effective work of the condenser and the maximum heat exchange, the outside

must be cleaned without any contaminants such as fallen leaves, lint, insects and the like that easily

block the condenser fins.

2. Inspection and cleaning of heat exchangers

To determine if the water side heat exchanger is clean, check the heat and water temperature of the

heat exchanger and compare it to the evaporation temperature. For example, if the outlet temperature

and the evaporation temperature differ by more than 5~7 °C at the rated water flow rate, the operating

efficiency of the heat exchanger has been reduced and cleaning is required.

Since some chemical treatment is required during the cleaning process, cleaning must be done by a

professional.

3. Replenishment of refrigerants and lubricants

Each unit is shipped with sufficient refrigerant R410A and lubricant. When the system is working properly,

there is no need to replenish refrigerant or lubricating oil, and it is not allowed to charge or replace

refrigerant and lubricant. If it is necessary to replenish due to leakage, please refer to the charging

amount specified on the nameplate on the unit.

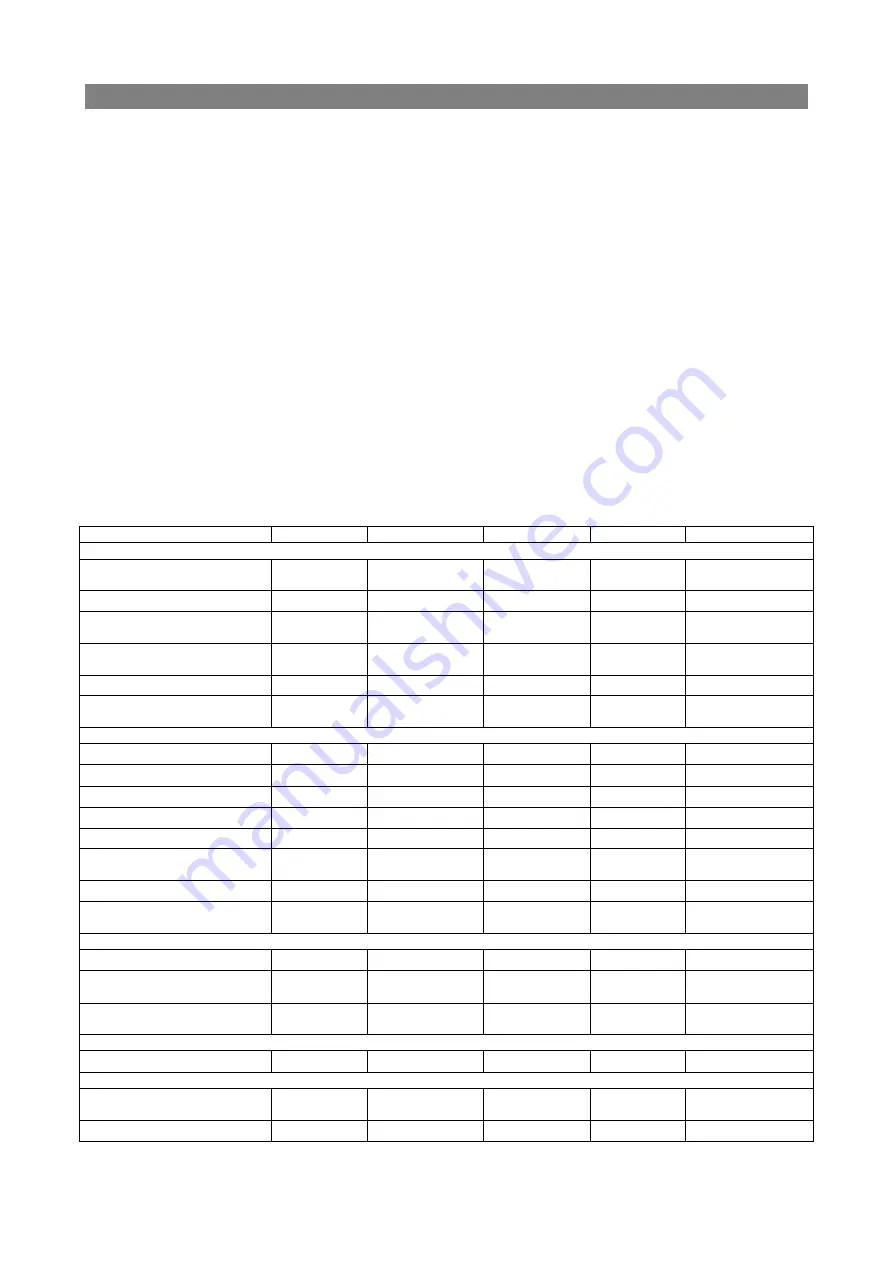

6.2 Maintenance

During the use of the unit, certain routine inspections must be carried out to ensure the performance of

the unit. This is also to avoid unnecessary downtime routine inspections including the following items:

Item details

per month

Each quarter

Half a year

One year

base on needs

1.Compressor

Performance evaluation, with

or without abnormal sound

●

Is the wiring secure

●

Whether

the

current

is

abnormal (within 10%)

★

Compressor

exhaust

temperature

★

Detecting oil level

★

Check the color of the

lubricant

★

2. Controller

Check parameter settings

★

Inspection protection

★

Delay protector

★

Phase sequence protector

★

High and low voltage switch

★

Water pressure difference

switch, water flow switch

★

Overload protector

★

Exhaust gas temperature

protector

★

3. Shell and tube heat exchanger

Check water quality

●

Cleaning shell-and-tube heat

exchanger

★

Seasonal

protection

measures (winter antifreeze)

★

4. Finned heat exchanger

Cleaning fins

★

5.other

Does the Y filter need to be

replaced and cleaned?

●

Is the unit screw loose?

●

Remarks: The above maintenance plan is only for guidance (for reference), and the specific

Summary of Contents for CA0065EANR

Page 8: ...5 1 2 Main components of the unit ...

Page 15: ...12 Installation 3 Diagram of arrangement of multiple chiller units Unit mm ...

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......