12

5.52.653.00.01.06

Records must be kept of all test results and measures taken.

12.2

Monitoring

The monitoring and servicing intervals stated are valid for operation under normal conditions and single-shift

operation. In case of severe operating conditions (e.g. frequent operation with full load) or special

environmental conditions (e.g., heat, dust, etc.), the intervals must be shortened correspondingly

12.3

Brake motor

Electric driven trolleys from 15t are equipped with a brake motor

Connection voltage for the brake 400 VAC

Coil voltage: 180 VDC

trolley

Capacity

t

Brake

type

Nominal brake

moment

Nm

Nominal air gap

mm

air gap

max.

mm

friction lining thick-

ness

min.

mm

15-50

BFK 06

4

0,2

0,5

1,5

12.3.1

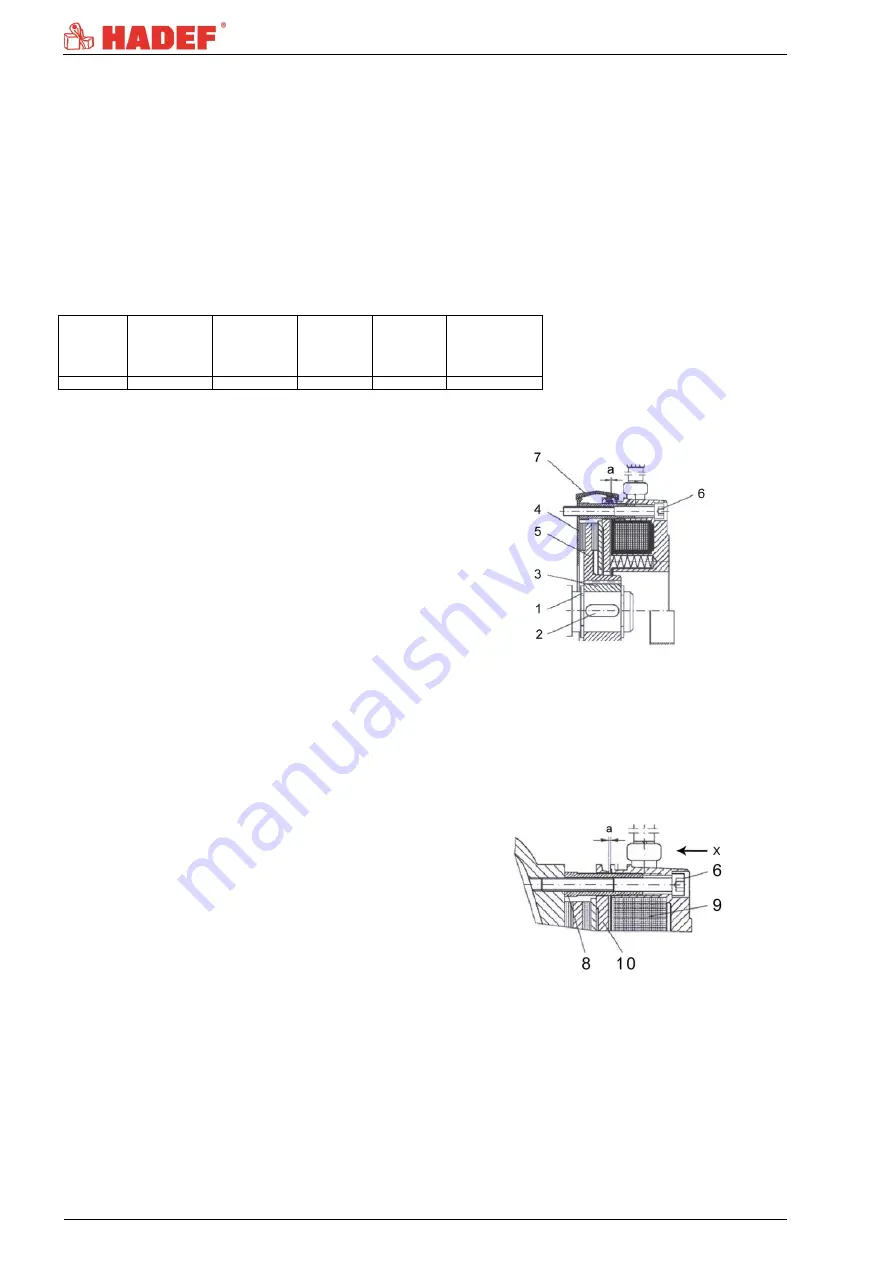

Assembling the brake

1 Insert the retaining ring (1) into the shaft slot.

2 Insert the feather key (2) into the motor shaft.

3 Fix hub (3) with retaining ring (1).

4 Assemble the friction plate (4) if existent.

5 Push the rotor (5) onto the hub (3).

6 Lock the magnet body with the 3 fastening

screws (6).

7

Set air gap “a” (refer to “adjusting the air gap”)

8 Assemble the dust-protection ring (7) if

existent.

9 Electric connection

Illustration 8

12.3.2

Disassembly of the brake

Disassembly is performed in reverse order to the assembly.

12.3.3

Adjusting the air gap

View "X" on the brake.

1 Loosen the locking screws (6) by half a turn.

2 Turn the cap screws (8) into the magnetic body

(9) anti-clockwise.

3 By turning the locking screws (6) clockwise,

move the magnetic body (9) towards the

anchor plate (10) using a feeler gauge until

nominal air gap “a” is reached (see table).

4 Unscrew the cap screws (8) from the magnetic

body clockwise.

5 Tighten the locking screws (6).

6 Check the air gap again and re-adjust if

necessary.

Illustration 9