Installation of gear reducer

5

Attention!

During the running the gear reducers could have hot surfaces; Always wait that the gear reducer or the

gearmotor to cool before carrying out any operations.

Further technical documentation can be downloaded from our website www.rossi.com.

Fitting of components to shaft ends

It is recommended that the bore of parts keyed to low speed shaft ends is machined to K7 tolerance (H7 when load is uniform

and light).

Before mounting, thoroughly clean mating surfaces with proper antirust products, and lubricate against seizure and fretting

corrosion.

Installing and removal operations should be carried out with pullers and jacking screws using the tapped hole at the shaft butt-end.

Tightening torques for fastening bolts (feet, fl ange, accessories) and for plugs

Unless otherwise specifi ed, it is normally suffi cient to use class 8.8 screws; the following cases are an exception, for which

screws with strength class 10.9 must be used:

•

iC 372 - iC 373 FE with fl ange F312

•

iC 472 - iC 473 FE with fl ange F414

•

iC 572 - iC 573 FE with fl ange F516

Before tightening, carefully degrease the screws; in the event of heavy vibrations, heavy duties, frequent drive inversions apply

a thread-braking seal type LOCTITE or similar.

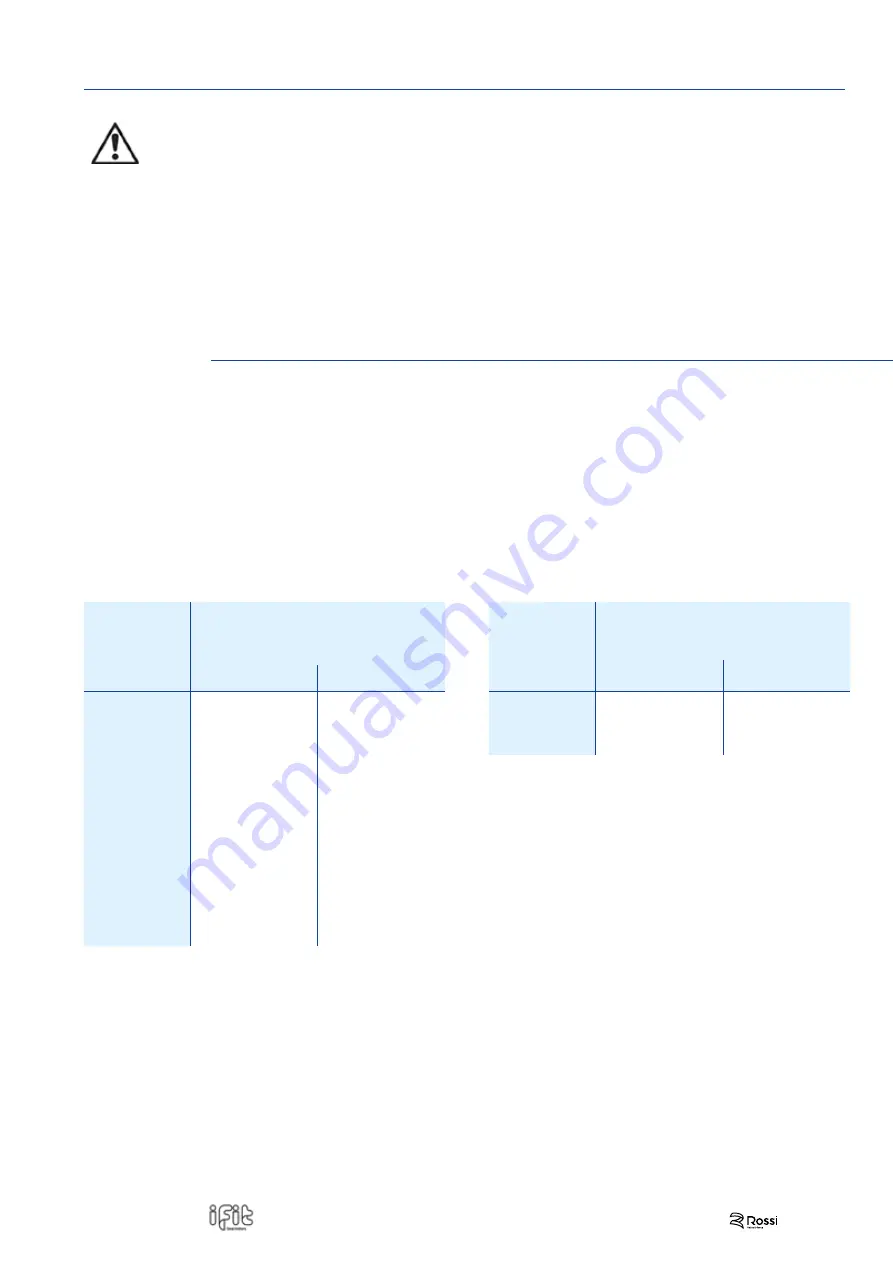

Fastening

bolts

Tightening torque Ms

for bolts for foot and fl ange fastening

N m

cl. 8.8

cl. 10.9

M4

2.9

4

M5

6

8.5

M6

11

15

M8

25

35

M10

50

70

M12

85

120

M14

135

190

M16

205

290

M18

280

400

M20

400

560

M22

550

770

M24

710

1000

Frame size

gear reducer

Tightening torque Ms

for oil drain and breather plugs

Plug threading

dimension

Ms

N m

iC 27 ... iC 67

M10 x 1

8

iC 77, iC 87

M12 x 1,5

14

iC 97

M22 x 1,5

45

Table 5.2.2 Tightening torques for oil drain and fi ller plugs

Table 5.2.1 Tightening torque for fastening bolts

5.2

15

UT.D 208-2021.12-EN