8-5

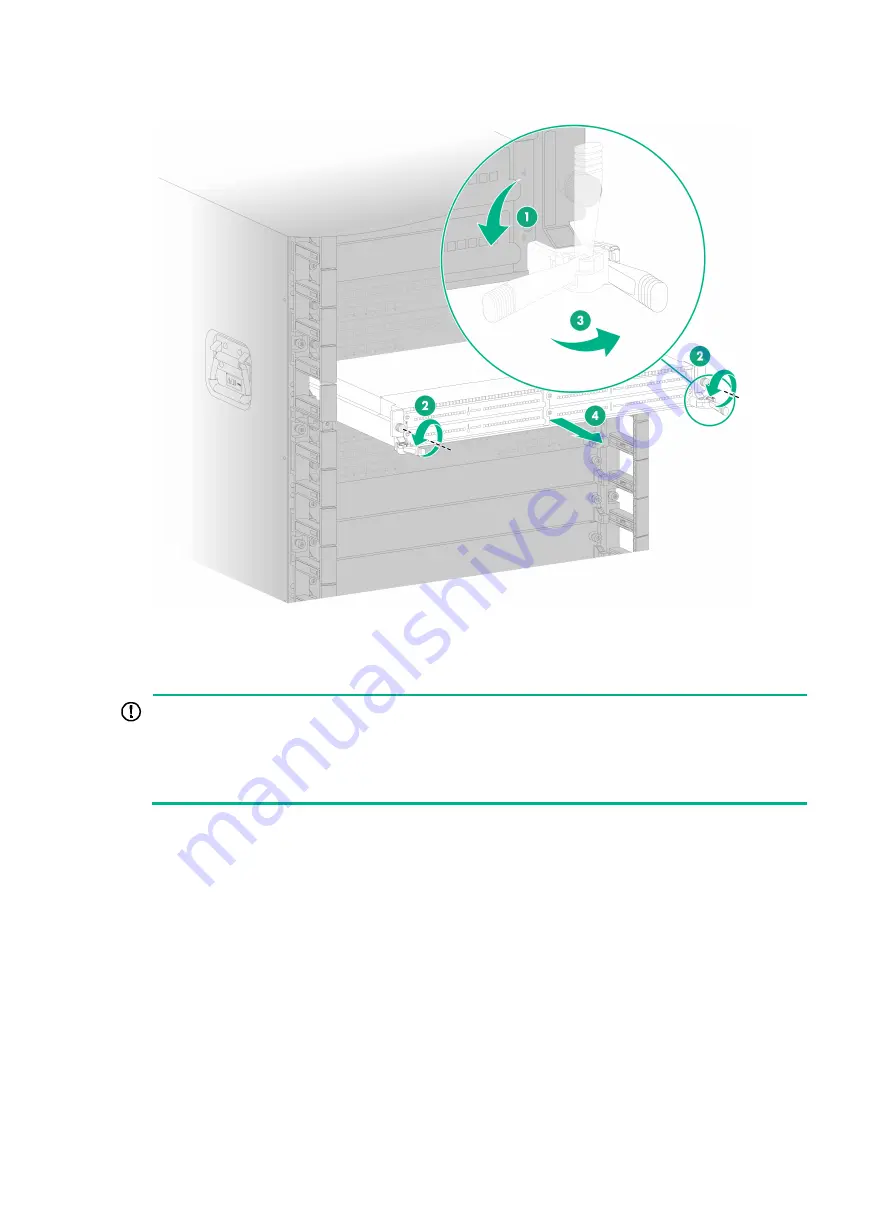

Figure8-4 Removing an interface module with ejector levers

Replacing an interface subcard

IMPORTANT:

•

If you are not to install a new interface subcard after removing the old one, install a filler panel in

the slot.

•

When installing a filler panel, orient it with the blade of the screwdriver image on it facing

upwards. First insert the filler panel right side into the slot, and then push the left side into the slot.

1.

Remove the cables from the interface subcard.

2.

Prepare an antistatic mat to place the removed interface subcard.

3.

Wear an ESD wrist strap. Make sure the wrist strap makes good skin contact and is reliably

grounded.

4.

Use a Phillips screwdriver to loosen the captive screws on the interface subcard.

5.

Open the ejector levers on the interface subcard and then pull the interface subcard part way

out of the slot.

6.

Supporting the interface subcard bottom with the left hand, slowly pull the interface subcard out

of the slot along the guide rails with the right hand.

7.

Place the removed interface subcard on the antistatic mat.

8.

Install a new interface subcard. For the installation procedure, see "Installing interface

subcards."

Summary of Contents for CR19000-20

Page 11: ...1 5 Figure1 1 Chassis dimensions...

Page 39: ...2 9 Figure2 7 Securing the router to the rack...

Page 61: ...4 2 Figure4 1 Slot arrangement...

Page 84: ...6 5 Figure6 4 Installing an air filter...

Page 97: ...8 9 Figure8 9 Removing a fan tray...

Page 103: ...8 15 Figure8 18 Securing the new power tray...

Page 131: ...11 7 Figure11 8 Routing AC power cords...