•

Do not use the pressure tank if it shows any faults that

could threaten employees or third parties.

•

The pressure tank needs to be regularly checked for

damage or rust.

•

If you identify any damage please contact the

customer service workshop.

Behaving in emergency

Introduce first aid corresponding to injuries and seek a

qualified medical person as soon as possible.

Protect the injured person against other injuries and calm

him/her down.

Use as designed

For blowing and soft works with compressed air, in clay-

modelling, for wall airbrush, airbrush varnishing, tire

pressure rating, etc.

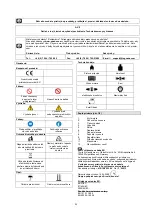

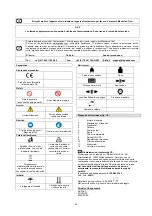

Residual risks and safeguards

Direct electric contact

Faulty cable or plug can lead to a life-threatening

electric shock.

Have the faulty cable or plug replaced by a professional.

Use the appliance on a connector with a safety switch

against stray current (FI) only.

Indirect electric contact

Injuries by conductive parts at exposed electric or

faulty construction parts.

Always pull the plug out of socket at maintenance. Use with

an FI switch only.

Insufficient local lighting

Insufficient lighting represents a high safety risk.

Always ensure sufficient lighting when working with the

appliance.

Disposal

The disposal instructions are based on icons on the

appliance or its package. The description of their meanings

can be found in the “Marking on Appliance“ Chapter.

Transport package disposal

The package protects the appliance against damage during

transport. Package materials are usually selected in terms

of environment protection and disposal manner and can be

recycled.

Putting the package back into circulation saves raw

materials for the material and cuts costs for material

processing.

Parts of the package (e.g. foils, styropor) can be dangerous

for children.

There is a risk of suffocation!

Keep parts of

the package out of reach of children and dispose them as

quickly as possible.

Handling requirements

The operating staff must carefully read the Operating

Instructions before using the appliance.

Qualification

Apart from the detailed instruction by a professional no

special qualification is necessary for using the appliance.

Minimum age

Only persons over 16 years of age can work with the

appliance.

An exception includes youngsters if they work within their

professional education whose purpose is to obtain knowledge

supervised by a trainer.

Training

Using the appliance only requires corresponding training by a

professional or following of the Operating Instructions. No special

training is necessary.

Transport and storing

•

At longer storing, the appliance needs to be thoroughly

cleaned and placed in a manner that no unauthorised persons

could access it.

•

Never store and transport the compressor horizontally and

under pressure!

•

The pressure in the air jet can be reduced at cooling the

compressed air.

Assembly / first putting into operation (pic. 5-8, 10)

Check the oil level at every start-up!!!

Before putting the compressor into operation, it is necessary

to replace the transport peg of the oil with an oil fill mouth and

correct oil level needs to be ensured.

Position the compressor on a horizontal, flat and sufficiently high

working surface to prevent compressor oil flowing out.

Due to transport, the compressor is not supplied in a completely

assembled state.

Now you need to mount the oil tank peg:

You must take the transport peg of the oil tank out and insert the

attached peg instead the correct oil level needs to be ensured, too.

Proceed as follows:

Take the transport oil peg out. Pour oil as much as to the

marking in the aperture. Then mount the oil fill mouth. When

emptying or changing the oil, screw the drain screw out.

Assembly of the transport wheels and the feet (Fig. 7 / 8)

Screw the transport wheels on each side with the supplied nuts and

washers to (you need a wrench is not included in the package is). In

Figure 7 you see the order of the Wheel:

• bolt through the hole in the wheel press

• Disc enclose

• wheel with screw and washer through the hole of the axle lead.

• washer on the bolt end slide

• Spring ring screws on the end slide

• Mother and turn well tighten.

Stand mount

The feet are as in (Fig. 8) to see tightened.

Handle assembly

The open ends of the handle, transport into the openings provided

on the compressor and slide through the enclosed wing screws.

Oil change (pic. 10)

Since arriving on the piston can chip, it is absolutely

necessary after the first 10 hours of operation to carry out an

oil change. We recommend that you are our compressor (SKU:

40056). Later, depending on the operation of the compressor,

all 100 to 200 hours of operation an oil change place. In order

to carry out oil changes, open the drain screw (16) and begin

the process of waste oil in a suitable container.

Observe strictly the rules for disposal of waste oil and

dispose of it properly in a waste oil collection center.

36

Summary of Contents for 410/10/50 230 V

Page 2: ...5 1 1 3 2 4 5 6 8 9 10 11 7 2 12...

Page 3: ...5 6...

Page 4: ...7 8...

Page 5: ...9 10 a...