GROWSPAN

™

ROLLING PREMIUM HIGH TUNNELS

18

Revision date: 01.01.16

FRAME ASSEMBLY

Gather the parts:

• All Rafter Assemblies (End and Interior)

• Pipe 1.315'' x 75'' swaged (#131S075)

• Pipe 1.315'' x 73.5'' plain) – See Side Profile Diagrams

in Quick Start section for quantities.

• Castors attached to 30R1904D rafter sections

• Lifts, ladders, tools, and assistants

Frame Assembly Procedure

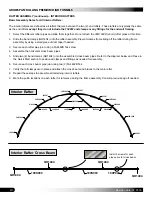

1. Using the proper lifts and with assistance, carefully

stand the first end rafter—one with end clamps—and

install the first set of end pipes with castors. Verify that

the rafter is set so that the 102857 end clamps are

positioned as shown below.

2. Center the castor on the track pipe and secure the

30R1904D pipe to the rafter using two (2) FA4482B Tek

screws.

3. Verify rafter is plumb and brace it in place using cables,

ropes, or dimensional lumber. Leave bracing in place

until additional rafters and purlins are installed.

IMPORTANT:

Brace

the first rafter in

position as needed to

keep it from moving.

Bracing is removed

after

additional

rafters are installed

and secured to the

other rafters.

Photo shows the first end rafter and first interior rafter set

in place on the track pipe. End rafter is secured to the site

using one of the anchor stakes included with the building.

Crew members

install the short

30R1904D rafter

pipe with castor.

Before securing

the pipe to the

main rafter using

two FA4482B Tek

screws, verify

that the castor is

centered on the

track pipe.

NOTE:

Sample rafter above is used to illustrate

bracing. Actual rafter may differ in design, width or

both.

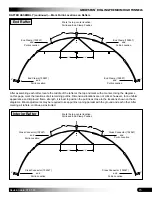

4. Place an interior rafter–one without end clamps—into

position and install the short pipe with castors (Steps 1

and 2) above.

To the

inside of

the shelter

End Rafter