-26-

Model G1015 (Mfg. since 7/99)

SECTION 6: MAINTENANCE

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check:

•

Loose mounting bolts.

•

Damaged or worn sanding belt.

•

Worn or damaged wires.

•

Any other unsafe condition.

Monthly Check:

•

Lubricate pivot arm bushing.

Schedule

Cleaning the Model G1015 is relatively easy.

Vacuum excess chips, sawdust, and debris, then

wipe off the remaining dust and grime with a dry

cloth. If any resin has built up, use a resin dissolv-

ing cleaner to remove it. Treat all unpainted cast

iron and steel with a non-staining lubricant after

cleaning.

Cleaning

Lubrication

Always disconnect power

to the machine before

performing maintenance.

Failure to do this may

result in serious person-

al injury.

The bearings for the Model G1015 were lubricated

and sealed at the factory. Merely leave them

alone unless they need replacement.

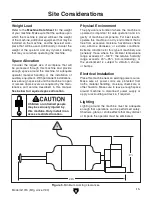

To lubricate the pivot arm bushing, remove the

sanding arm assembly and pivot arm, then apply

a light coat of multi-purpose grease to the outer

surface of the bushing (see

Figure 32).

Figure 32. Pivot arm bushing.

Bushing

Summary of Contents for G1015

Page 15: ...Model G1015 Mfg since 7 99 13 5mm Hardware Recognition Chart...

Page 40: ......