Model G0787 (Mfd. Since 09/14)

-17-

Disc Sanding

Only sand workpiece on side of sanding

disc that is rotating down toward work table.

This will keep workpiece from flying out of

your hands from rotational force of disc.

Set the work table angle relative to the sanding

disc. The angle can be set using the angle scale

on the sander body, or for greater accuracy, a pro-

tractor or machinist's square can be used.

Setting Work Table Angle

Adjusting Miter Gauge Angle

To set work table angle:

1. DISCONNECT MACHINE FROM POWER!

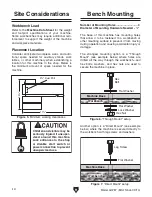

2. Loosen angle adjustment knob, and position

work table so pointer on end of work table

support aligns with desired angle on angle

scale (see

Figure 15).

— For greater accuracy, use a protractor

or machinist's square.

Performing Disc Sanding Operations

For disc sanding straight lines, always brace your

workpiece against the miter gauge for maximum

stability. We do not recommend disc sanding with-

out a miter gauge unless absolutely necessary, as

with sanding outside curves. For more informa-

tion, see

Sanding Outside Curves on Page 18.

To perform disc sanding operations:

1. Set work table and miter gauge angles, as

described on this page.

2. Turn machine ON.

1. Place miter gauge in slot in work table, then

loosen miter gauge lock knob shown in

Figure 16.

Figure 16. Setting miter gauge angle.

2. Rotate fence until pointer indicates desired

angle on scale, then re-tighten lock knob.

Note: For instructions on calibrating your

miter gauge, see

Calibrating Miter Gauge

on

Page 28.

Miter Gauge

Lock Knob

Pointer

Scale

Fence

Work Table

Support

Pointer

Figure 15. Setting work table angle.

3. Re-tighten angle adjustment knob.

Angle

Scale

Square

Angle

Adjustment

Knob

Summary of Contents for G0787

Page 40: ......