Model G0634Z/G0634XP (Mfd. Since 01/20)

-69-

BUY PARTS ONLINE AT GRIZZLY.COM!

Scan QR code to visit our Parts Store.

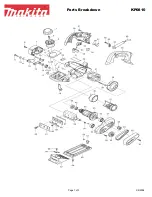

Planer Table

404

405

411

402

403

409

407

401

406

415

408-1

419

410

417

418

420

421

422

423

424

425

414

421

412

413

437

438

427

428

429

430

434

421

433

426

436

431

432

414

420

435

434

408-2

408

REF PART #

DESCRIPTION

REF PART #

DESCRIPTION

401

P0634Z401

PLANER TABLE

420

P0634Z420

BUSHING

402

P0634Z402

COLUMN

421

P0634Z421

FLAT WASHER 5/16

403

P0634Z403

CYLINDER LINER

422

P0634Z422

LOCK NUT 5/16-18

404

P0634Z404

LOCK SCREW

423

P0634Z423

LOCK WASHER 1/4

405

P0634Z405

COLLAR

424

P0634Z424

CAP SCREW 1/4-20 X 2-1/4

406

P0634Z406

THICKNESS POINTER

425

P0634Z425

INT RETAINING RING 8MM

407

P0634Z407

GEAR BOX

426

P0634Z426

ROLL PIN 5 X 30

408

P0634Z408

BUSHING

427

P0634Z427

SET SCREW 5/16-18 X 1/4

408-1 P0634Z408-1 SELF-LUBRICATING SHLDR BUSHING

428

P0634Z428

FENDER WASHER 13.5 X 34 X 4MM

408-2 P0634Z408-2 SELF-LUBRICATION BUSHING

429

P0634Z429

LOCK WASHER 3/8

409

P0634Z409

GEAR

430

P0634Z430

HEX BOLT 3/8-16 X 1-1/2

410

P0634Z410

WORM SHAFT

431

P0634Z431

SET SCREW 5/16-18 X 1

411

P0634Z411

ELEVATION LEAD SCREW

432

P0634Z432

CAP SCREW 3/8-16 X 1-1/4

412

P0634Z412

SHIELD PLATE

433

P0634Z433

HEX BOLT 5/16-18 X 1/2

413

P0634Z413

HANDWHEEL

434

P0634Z434

HEX NUT 3/8-16

414

P0634Z414

HEX NUT 5/16-18

435

P0634Z435

SET SCREW 3/8-16 X 2

415

P0634Z415

UNIVERSAL LOCK LEVER

436

P0634Z436

PHLP HD SCR 5/16-18 X 3/4

417

P0634Z417

ROLL PIN

437

P0634Z437

HANDLE

418

P0634Z418

THRUST BEARING N2AS

438

P0634Z438

SHOULDER SCREW 3/8-16 X 5/8, 3/8 X 2-1/2

419

P0634Z419

INT RETAINING RING 19MM

Summary of Contents for G0634Z insert

Page 92: ......