SUPER SPORTSTER 60 PARTS LIST

PART# QTY DESCRIPTION

Balsa 3/32 x 1/4 x 36 Cap Strip

Balsa 3/32 x 3 x 7 Center Sheet

Balsa 1/4 Triangle Fuselage Brace

Balsa 1/8 x 1/4 x 36 Former Stock

Balsa 3/32 x 3 x 24 Bottom Fuse Sheeting

Balsa Shaped 5/8 Chin Block

Balsa Shaped 1/4 Center rib

Plastic Canopy

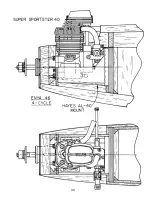

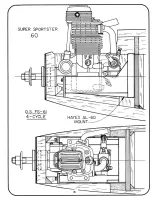

Adjustable Engine Mount Left

Adjustable Engine Mount Right

Instructions

CA Hinge Strip 2 x 9

Balsa Shaped 3/16 Fuselage Sides

Balsa Shaped 1/8 Deck Base

Ply 1/4 x 3-1/4 x 2-15/16 Bulkhead #1

Ply Shaped 1/4 Bulkhead #2

Balsa 1/4 x-3-5/16 x 3-9/16 Bulkhead #3

Balsa 3 / 8 x 4 x 1 1 -3/4 Hood Top

Balsa 1/4 x 1-3/8 x 18 Nose Side

Balsa Shaped 1/2 Nose Side Block

Balsa 3 / 8 x 1 2 Triangle Stock

Basia 1 / 4 x 3 x 1 0 Wing Filler

Balsa 1/8 x 3-1/4 x 6-1/8 Cockpit Floor

Plan Sheet

Balsa Shaped 1/4 Fin Front

Balsa Shaped 1/4 Fin Rear

Balsa Shaped 1/4 Rudder Front

Balsa Shaped 1/4 Rudder Rear

Balsa Shaped 3/8 Stabilizer Front

Balsa Shaped 3/8 Stabilizer Rear

Balsa Shaped 3/8 Elevator

Balsa Shaped 7/8 Wing Fairing

Balsa 1 / 2 x 2 x 6 Wing Fairing

Balsa Shaped 3/16 Wing Tip

Plastic ABS Wheel Pant Set

SUB PACK - FUSE & WING

Hardwood Shaped 5/8 LG Gusset

Hardwood Grooved 5/8 x 4-1/2 LG Block

Hardwood Grooved 5/8 x 3/4 LG Block

Hardwood 1 / 2 x 1 x 3 Wing Hold Down

Plywood Shaped 1/16 LG Brace

Plywood 1/16 Spinner Ring

Plywood 1/16 x 2-5/8 x 3-1/2 Wing Plate

Plywood 1/2 x 5/8 x 3-5/16 Hold Down

SUB PACK - BALSA PARTS

Balsa Shaped 7/16 Filler (LE)

Balsa 2-1/2x 2-5/8 x 1/2 Filler

Balsa Shaped 1/4 Former 1A

Balsa Shaped 1/4 Former 2A

Balsa Shaped 1/4 Former 3A

Balsa Shaped 1/4 Former Dash

Balsa Shaped 1/4 Former 6A

Balsa Shaped 3/4 Fin Filler Block

Balsa Shaped 1/2 Center Trailing Edge

BAL009

BAL015

BAL019

BAL047

BAL084

BAL116

BAL120

CANPY025

EM4070L

EM4070R

SS246P02

NYLON87

SS60F01

SS60F02

SS60F03

SS60F04

SS60F05

SS60F07

SS60F09

SS60F10

SS40F29

SS40W14

SS60F30

SS60P01

SS60R01

SS60R02

SS60R03

SS60R04

SS60S01

SS60S02

SS60S03

SS60W07

SS60W08

SS60W10

WPNT003

SS60A01

HRDWD005

HRDWD010

HRDWD013

HRDWD017

PLY3004

PLY3016

PLY3017

SS60F17

SS60A02

BAL103

SS60F16

SS60F18

SS60F19

SS60F20

SS60F21

SS60F24

SS60F28

SS60W11

5

8

3

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

2

1

2

2

1

1

2

2

2

2

4

1

1

2

1

4

1

1

1

1

1

1

2

2

SS60A04

SS60F33

SS60W12

SS60F35

SS60F31

SS60F11

SS60F12

SS60M01

GLTP001

METAL007

NUTS003

NYLON03

NYLON 13

NYLON16

NYLON17

NYLON20

NYLON21

NYLON36

PLY3013

PLTB002

SCRW002

SCRW005

SCRW008

SCRW020

SCRW024

WBNT002

WBNT009

WBNT101

WHCL005

WIRES16

WIRES17

SS60M02

WBNT085

WBNT086

SS60W01

BAL025

BAL060

BAL063

BAL118

SS60W03

SS60W04

1

1

5

2

1

1

8

1

1

2

4

2

4

1

2

2

2

1

2

2

4

1

4

1

12

1

1

1

2

2

2

1

2

1

1

4

4

3

2

4

2

PART# QTY DESCRIPTION

SUB PACK - RIBS AND FORMERS

Balsa 1/8 Former 3B, 4A, 5A, 6B (Die-Cut)

Balsa 3/32 Wing Ribs (Die-Cut)

Ply 1/8 Fuse Doubler (Die-Cut)

SUB PACK - FUSE STRINGER

Balsa 1/4 x 1/4 x 17-1/2 Stringer

Balsa 1/8 x 1/4 x 17-1/2 Stringer

SUB PACK - HARDWARE

Fiberglass Tape 1 x 8

Brass Shaped 1/16 Plate

6-32 Blind Nuts

Nylon Control Horns

Nylon 1/4 - 20 Wing Bolt

Nylon 5/32 Nosegear Steering Arm

Nylon Clevis

Nylon Swivel

Nylon Swivel Clevis

Nylon Gear Hold Down Straps

Plywood 1 / 8 x 1 / 2 x 1 Plate

Plastic 36" Outer Pushrod Tube

2-56 x 5/8 Screw

6-32 x 1/8 Screw

6-32 x 1 Screw

6-32 x 1/4 Screw

#2 x 3/8 Screw

Wire 3/32 Aileron Torque Rod Set

Wire Tailgear Assembly

Wire Elevator Tie

5/32" Wheel Collar

Threaded Pushrod Wire - 16"

Threaded Pushrod Wire - 34"

SUB PACK - LANDING GEAR

Wire Main Gear

Wire Nose Gear

SUB PACK - WING PARTS

Balsa 3/8 x 1/2 x 29-1/2 Spar

Balsa 3/32 x 7/8 x 30 TE Sheeting

Balsa 1 / 4 x 3 / 4 x 3 0 LE

Balsa Shaped 1/2 x 30 Aileron

Balsa 3/32 x 3-1/4 x 30 LE Sheeting

Balsa 1 / 4 x 5 / 1 6 x 3 0 TE

40

Summary of Contents for Super Sportster 20

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36...

Page 37: ...37...

Page 41: ...Use trim MonoKote and these letters to create your trim scheme on your Sportster 41...

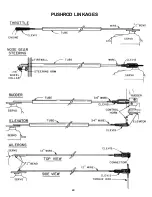

Page 43: ...PUSHROD LINKAGES 43...