Start with the right aileron.

❏ ❏

1. Cut the covering from the right aileron servo mount

in the bottom of the wing. Hint: Cut the covering 1/8" [3mm]

inside the edges, then use a trim iron to seal the covering to

the edges.

❏ ❏

2. Connect a servo extension cord to the aileron servo

wire. Secure the connection with vinyl tape, heat shrink

tubing, or special clips suitable for that purpose.

❏ ❏

3. Tie the end of the string that is taped inside the

wing to the end of the servo wire. Pull the wire through.

Note: If something happens to the string such as it breaks

or it cannot be located, don't worry. Tie another piece of

string to the servo wire and tie a weight (such as a wheel

collar) to the other end of the string. Place the wing on end

and drop the weight down through the holes in the ribs. Pull

the end of the string out of the hole in the middle of the wing.

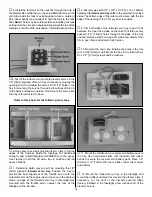

Refer to this photo for the following two steps.

❏ ❏

4. Drill 1/16" [1.6mm] holes in the wing for mounting the

aileron servo. Add a few drops of thin CA to the holes and

allow to harden. Mount the servo to the wing. Note that, for the

right aileron servo shown in the photo, the servo arm points

towards the middle of the wing and the output shaft is toward

the trailing edge. The left aileron servo is mounted in a “mirror”

image (with the servo arm pointing toward the middle of the

wing and the output shaft toward the trailing edge).

❏ ❏

5. Thread a nylon clevis twenty full turns onto a 6"

[150mm] threaded pushrod. Connect the clevis to a control

horn with a silicone retainer over the clevis. Place the control

horn on the aileron so the pushrod is in alignment with the

servo arm. Use a felt-tip pen to mark the pushrod over the

holes in the servo arm. Bend the pushrod at the mark, then

fit a nylon Faslink (shown in the sketch above) to the

pushrod. Cut the pushrod so 1/16" [2mm] protrudes from the

Faslink. If necessary, enlarge the holes in the servo arm with

a #48 (or 5/64" [2mm]) drill. Connect the pushrod to the

servo arm with the Faslink.

❏ ❏

6. Drill 1/16" holes into the aileron for mounting the

control horn with two #2 x 1/2" [13mm] screws. Add a few

drops of thin CA to the holes and allow to fully harden.

Mount the control horn to the aileron with two #2 x 1/2"

[13mm] screws. Be certain the screws are secure and get a

good “bite” into the wood. If necessary, remove the screws,

add a few more drops of thin CA to the holes and allow to

harden. Remount the control horn.

❏

7. Mount the left aileron servo and make the pushrod

the same way. Install the screws that hold the servo arms to

the servos.

❏

1. Use epoxy to glue the three plywood forward wing

joiners together. Wipe away excess epoxy before it hardens.

Join the Wing

Servo Arm

Hook Up the Ailerons

9