6

24

24

16

4

17

18

22

23

21

7

7

1

3

5

2

1

13

12

19

6

14

11

10

15

8

9

20

1

Wing with Ailerons

2

Fuselage

3

Stab with Elevators

4

Fin with Rudder

5

Cowl

6

Cowl Ring

7

Wheel Pants

8

Rudder Fairing

9

Turtledeck

10

Fin Fairing

11

Stab Fairings

12

Wing Bolt Plate

13

Forward Wing Joiners

14

Wing Struts

15

Dorsal Fin

16

Engine Mount

17

Fuel Tank

18

Cockpit Coaming

19

Main Landing Gear

20

Tailgear

21

Aft Wing Joiner

22

Forward Servo Tray

23

Aft Servo Tray

24

Main Wheels

(1) 2-3/4" [70mm] spinner

(2) Decal sheets

(1) CA hinge strip

(2) 2-56 x 6" [150mm] pushrods (ailerons)

(4) Large control horns (ailerons, elevators)

(38) #2 x 1/2" [13mm] screws

(2) Nylon Faslinks (ailerons)

(3) Nylon clevises (ailerons - 2, throttle - 1)

(7) Silicone clevis retainers (clevises)

(8) 1/8" [3mm] flat nylon straps (main LG)

(4) 3 x 6mm socket head cap screws (LG axles)

(4) 5mm wheel collars (main wheels)

(4) 3mm set screws for wheel collars

(2) 4-40 x 36" [910mm] wire pushrods (elevators)

(4) 2-56 x 3/4" [19mm] screws (elev cntrl horns)

(2) Large metal solder clevises (elevators)

(2) 4-40 metal threaded clevises (elevators)

(2) 4-40 nuts (for clevises)

(1) 6-32 x 1-1/2" [38mm] threaded rod (rudder)

(2) 4-40 nylon torque rod horns (rudder)

(2) 1/8" [3mm] nylon hump straps (tail gear)

(1) 36" [910mm] gray inner pushrod tube (tail

gear, antenna tube)

(1) 3/16" x 36" [910mm] pshrd tube (tail steering)

(1) 2-56 x 36" [910mm] wire pshrd (tail steering)

(2) brass screw-lock connector body

(2) 4-40 x 1/8" [3mm] screws (for screw-lock)

(2) nylon retainers (for screw-lock)

(1) nylon ball link (tail steering)

(1) 0-80 threaded ball (tail steering)

(1) 0-80 nut (for threaded ball)

(2) 1/4-20 blind nuts (factory installed)

(2) 1/4-20 x 2" [50mm] nylon wing bolts

(8) #4 x 5/8" [16mm] scrws (cwl mnt, wing struts)

(4) #4 washers (cowl mounting)

(4) #4 lock washers (cowl mounting)

(6) #2 washers (servo tray)

(1) 2-56 x 18" [460mm] wire pushrod (throttle)

(1) 3/16" x 12" [21 x 305mm] pushrod tube

(1) 1/4" x 1/2" x 6" [6 x 13 x 150mm] balsa stick

(2) 1/4" x 3/8" x 6-1/4" [6 x 10 x 160mm]

hardwood sticks

(2) Axles

(4) 1/32" x 3/4" [1 x 20mm] plywood discs

(8) 8-32 x 1" [25mm] socket head cap screws

(4) #8 washers (engine mount)

(8) #8 lock washers (eng mnt, eng mounting)

(4) 8-32 blind nuts (engine mount)

(4) Cowl mount blocks

(2) Windscreens

(2) Wing dowels

Rudder pull/pull components:

(1) Metal cable

(4) copper swages

(4) 2mm metal clevises

(4) 2mm brass couplers

(4) 2mm nuts

(4) silicone clevis retainers

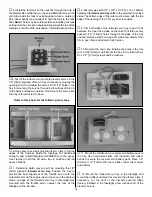

Kit Contents (Photographed)

Kit Contents (Not Photographed)

Before starting to build, use the Kit Contents list to take an inventory of this kit to make sure it is complete and inspect

the parts to make sure they are of acceptable quality. If any parts are missing or are not of acceptable quality, or if you

need assistance with assembly, contact Great Planes Product Support. When reporting defective or missing parts, use

the part names exactly as they are written in the Kit Contents list on this page.

Great Planes Product Support:

Phone: (217) 398-8970

Fax: (217) 398-7721

E-mail: [email protected]

KIT CONTENTS