❏

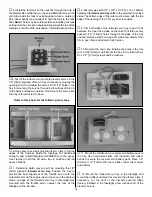

1. Use 30-minute epoxy mixed with lightweight Top Flite

Microballoons Filler to glue the 1/8" [3mm] plywood cowl

ring inside the cowl an equal distance from the aft edge all

the way around. The distance should be approximately 1"

[25mm] to 1-3/8" [35mm]–wherever it fits best. Set the cowl

aside and allow the epoxy to harden.

❏

2. Cut the holes in the front of the cowl for the engine crank

shaft and for the air inlets where shown. (Though not marked

on the cowl, for scale effect, an additional round hole was cut

to match the hole on the full-size STA-M.) A Dremel with a

carbide cutter, followed by a drum sander, works best for

cutting the holes. Use protective goggles and a particle mask

when cutting fiberglass. Finish by sanding the openings by

hand with 400-grit sandpaper to smooth the edges.

❏

3. Determine your engine exhaust configuration. With the

O.S.

®

MAX .91 Surpass

™

II used on this model, an O.S. “in”

type exhaust header pipe (OSMG2624) was used to

position the muffler near the bottom of the cowl. (This

requires removing a portion of the bottom of the plywood

cowl ring to accommodate the muffler.)

❏

4. Make two upper cowl mount blocks and two lower

cowl mount blocks to fit the full-size drawings above from the

9/16" x 9/16" x 1-3/16" [14.3 x 14.3 x 30mm] hardwood blocks.

❏

5. Use coarse sandpaper to roughen the fuelproof

coating where the cowl mount blocks will be glued (indicated

by the arrows) so the epoxy will adhere. Temporarily hold the

cowl mount blocks in position with a rubber band.

❏

6. Test fit the cowl. The cowl should not fit tightly over the

blocks. There should be approximately 1/32" [.8mm] between

the cowl and the mounting blocks. If necessary, trim the cowl

mount blocks to get the cowl to fit correctly.

Lower

Cowl

Mount

Upper

Cowl

Mount

Mount the Cowl

22