NOTE: The control throws are measured at the widest part

of the elevators, rudder and ailerons. It is likely that the

recommended rudder control throws will not be achieved by

adjusting the linkages mechanically (by changing the

position of the clevises on the servo arm). Instead, the

transmitter ATV will probably have to be used for this. The

ATV in the transmitter used to fly the prototypes was set to

70% to achieve the correct rudder throw.

NOTE: This procedure is not to be confused with balancing

the model (checking the C.G.). That important step will be

covered after this procedure.

❏

1. With the wing level, have an assistant help you lift the

model by the engine propeller shaft and the bottom of the

fuse under the trailing edge of the fin. Do this several times.

❏

2. If one wing always drops when the model is lifted, it means

that side is heavy. Balance the airplane by adding weight to the

other wing tip. An airplane that has been laterally balanced

will track better in loops and other maneuvers.

At this stage the model should be in ready-to-fly condition

with all of the systems installed including the engine, landing

gear, propeller and spinner and the radio system. The fuel

tank should be empty.

❏

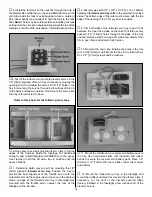

1. If using a Great Planes C.G. Machine

™

to balance the

model, set the rulers on the C.G. Machine to 4-3/16"

[106mm]. If you do not have a Great Planes C.G. Machine,

use a felt-tip pen or 1/16" to 1/8" [1.5 to 3mm] tape to

accurately mark the C.G. 4-3/16" [106mm] from the leading

edge next to both sides of the fuselage on the top of the wing.

❏

2. Mount the wing to the fuselage. If using a C.G.

Machine, place the model on the machine. If not using a

C.G. Machine, lift the model upside-down at the balance

point marked on top of both sides of the wing using the tip

of your middle finger on both hands.

This is where the model should balance for the first flights.

Later, you may wish to experiment by shifting the C.G. up

to 1/4" [6mm] forward or 1/4" [6mm] back to change the

flying characteristics. Moving the C.G. forward will

increase stability, but will decrease the model's aerobatic

capabilities by decreasing maneuverability. Moving the

C.G. aft will have the opposite effect. In any case, as long

as the model is balanced within the recommended

range it will not display any bad tendencies. Do not at any

time balance the model outside the recommended range.

More than any other factor, the C.G. (center of gravity, also

referred to as the balance point) can have the greatest

effect on how a model flies and may determine whether or

not your first flight will be successful. If you value this model

and wish to enjoy it for many flights, DO NOT OVERLOOK

THIS IMPORTANT PROCEDURE. A model that is not

properly balanced will be unstable and possibly unflyable.

Balance the Model (C.G.)

Balance the Model Laterally

We recommend the following control surface throws:

High Rate

Low Rate

ELEVATOR:

1" [25mm] up

3/4" [19mm] up

1" [25mm] down

3/4" [19mm] down

RUDDER:

1-9/16" [40mm] right 1-3/8" [35mm] right

1-9/16" [40mm] left

1-3/8" [35mm] left

AILERONS:

3/4" [19mm] up

1/2" [13mm] up

3/4" [19mm] down

1/2" [13mm] down

IMPORTANT: The balance point and control surface throws

listed in this manual are the ones at which the Ryan flies

best. Set up your aircraft to those specifications. If, after a

few flights, you would like to adjust the throws or C.G. to suit

your tastes, that is fine. Too much control surface throw can

make your model difficult to control or force it into a stall, so

remember “more is not always better.”

28