10

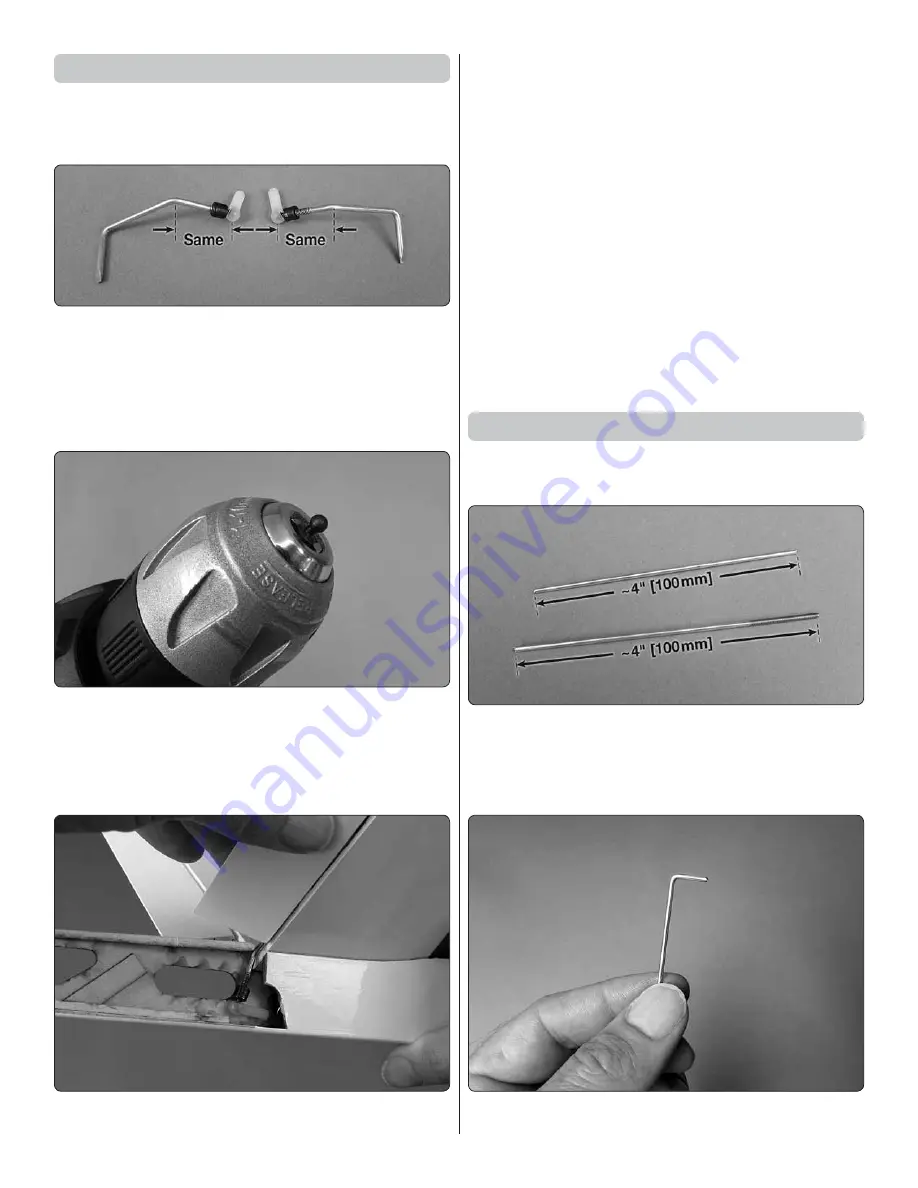

Test Fit the V-Tail

Do not use any glue until instructed to do so—we’re going

to go as far as possible fi tting up the V-tail and hooking

up the pushrods before permanently gluing anything in.

❏

1.

Temporarily

thread the ball link balls onto the

ruddervator torque rods. Examine the ball link balls to

make sure there is no burr or a sharp point on the tip. If

necessary, use a metal fi le to grind off the protrusion, then

snap the ball links onto the balls. Also make sure the ball

link balls are the same length. If necessary, shorten the

longer torque rod to match the short one.

❏

2. Make sure the ball links can move freely and are not

too tight. If they are too tight, chuck the base of the ball in

a hand drill (or, try another ball link if you have a supply of

your own). Polish the ball with metal polish and a cloth or

other mildly abrasive product until the ball links swivel on

the balls smoothly. Temporarily reassemble and set aside.

❏

3. Temporarily fi t the V-tail to the fuselage (being certain

to key the tab at the front of the V-tail center rib into the

notch in the former and the tab on the bottom into the

slot in the base). Without glue, test-fi t the ruddervators

with the hinges, torque rods and ball links. Make sure

the ruddervators move smoothly and the ball links don’t

interfere with anything. Make any adjustments necessary.

❏

4. If you haven’t yet done so, program your radio for

V-tail

mixing.

Now it’s time to decide what kind of pushrods you are

going to use—either the included rod-and-tube setup,

or an optional 5/32" [4mm] carbon fi ber pushrods (not

included). Most pilots use the standard wire pushrods,

but some pylon racers prefer carbon fi ber pushrods for

ultimate precision.

If using the pushrods included, skip to

Make the Wire

Pushrods

on page 13. If using carbon fi ber pushrods,

follow these instructions, or use your preferred method to

make the pushrods:

Make the Carbon Fiber Pushrods

The instructions illustrate making one pushrod at a time,

but you could make them simultaneously.

❏

1. Cut two, approximately 4" [100mm] segments from

the threaded end of one of the long pushrod wires so you

have a threaded piece and a non-threaded piece. Clean

the wires with denatured alcohol, then roughen with

medium-grit sandpaper so glue will adhere.

❏

2. Make a 90° “L-bend” as

sharp

as you can on one of

the non-threaded wires.