9

8

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

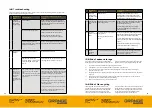

TABLE 1.0: RISK ASSESSMENT: USE OF GRANGE 3M LDT

1.0: Activity

2.0: Hazard

3.0: Persons

who might be

harmed

4.0: Applicable

sections in this

manual

5.0: Residual risk

(responsibility of end-user)

6.0: Overall

risk rating

Lifting &

slinging of

3m LDT

Cuts / bruises

Crush injuries

Haulage

driver, other

persons in

immediate

area

5.0; 6.0; 7.0;

8.0; 15.0

Only use approved lifting

systems and slings / hooks.

Lift only from the specified lift

locations.

Contact Grange Machinery Ltd

for replacement components if

any damage occurs to lifting &

slinging eyes.

MEDIUM

Connecting up

to the tractor

Cuts / bruises

crush and

entrapment.

Operator and

by-standers

4.0; 5.0 8.0; 9.0;

10.0

Only trained and authorised

personnel to operate tractor

coupled to Grange 3m LDT.

Operators to read this manual

and understand content before

use of Grange 3m LDT.

Verify tractor front ballast

requirements.

LOW /

MEDIUM

Maintenance

schedules

Cuts / bruises /

entrapment

Operator

4.0; 8.0; 13.0;

14.0; 15.0

Use of compliant axle stands

systems for supporting Grange

3m LDT. Use of appropriate tools

and PPE. Adhere to maintenance

schedules.

MEDIUM

Use of

2nd stage

cultivation

/ seeding

equipment

Cuts / bruises /

entrapment

Operator

4.0; 5.0; 10.0;

11.0

Uses of compliant coupling pins

with securing lynch pins.

Set-up 2nd stage cultivation/

seeding equipment in

accordance with relevant

operators manual. Verify tractor

front ballast requirements.

LOW /

MEDIUM

Transportation

on the public

highway

Road traffic

incident

with other

road users.

Collision with

pedestrians.

Other road

users and

pedestrians

4.0; 9.0; 10.0;

11.0

Adhere to public highway

legislation and any specific

weight limit restrictions on

routes. Check all tractor and

machinery couplings are secure

& lighting / braking systems

functioning correctly.

MEDIUM

Setting up in

the field and

use for tillage

operations.

Cuts / bruises /

entrapment

Operator

4.0; 5.0; 12;0;

13.0; 14.0; 16.0

Operate Grange 3m LDT

and 2nd stage cultivation/

seeding equipment to suit soil

conditions. Apply safe working

practices for any maintenance

activities undertaken in the field.

LOW /

MEDIUM

The risk assessment summarised below in Table

1.0 demonstrates how the design specification of

the Grange 3m LDT when operated in accordance

with the guidance from this operators manual have

reduced the risk to operators and other persons

to an acceptable level. The risk assessment also

identifies what further control measures are

required by the end-user when operating the

Grange 3m LDT.

OVERALL RISK RATING – REF COLUMN 6.0

LOW

The operation and use of the Grange 3m LDT presents a low level of

risk.

MEDIUM

Please note; some hazards may occur during operation with the use

of the Grange 3m LDT which require the operator to demonstrate

caution. For example when the Grange 3m LDT is in a raised position

or during transport mode. Also take care when operating tractor

controls and undertaking linkage connections.

HIGH

Please note; extreme caution is required during all operational use

of the Grange 3m LDT.

3.1 Risk assessment for use of Grange 3m LDT across its

intended lifecycle