29

28

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Please note!

i. Never try turning bends with the Grange 3m LDT legs in the ground.

ii. Always lift the legs out of working position before turning on

headlands or short turns.

13.0 Maintenance

The maintenance routines which are required on the Grange 3m LDT

equipment are as follows;

i)

Check all nuts and bolts after the first two hours use and then

check weekly.

ii)

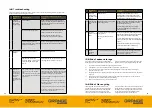

Regular greasing of the ram pivot points. (Ref: fig 14.0).

iii) Replacement of shear bolts in the event of excessive forces

applied to the tine. (Ref: fig 15.0 & 16.0).

Note the position of

the bolt head is always on the lower leg outside face when

replacing the shear bolt.

iv) Replacement of the tines when worn.

v)

Replacement of the cutting discs when worn.

vi) Replacement of the cutting disc bearings when failure occurs.

vii) Replacement of hydraulic ram seals in the event of failure.

FIG 14.0 GREASE LOCATIONS

FIG 11.0 3M LDT SETUP IN WORKING POSITION

FIG 12.0 LOCATION OF DISC RAM SPACERS

FIG 13.0 LOCATION OF DEPTH SPACERS

ON MAIN BEAM RAM

12.1 Headland turns and working sequence

i. Upon reaching the headland turn the beam will be in its lowest working position

with the cutting discs and legs engaged in the soil.

ii. Operate the auxiliary hydraulics until the beam lifts to the top of the ram travel, with

the legs exiting work. Maintain activation of the auxiliary hydraulics to rotate the

cutting discs out of work.

12.2 Back into work after headland turn

i. Activate the auxiliary hydraulics to lower the beam to engage the legs into the soil to

the set working depth.

ii. Maintain activation of the auxiliary hydraulics to rotate the cutting discs into work.