27

26

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

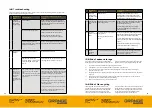

11.1 Road Vehicles (Construction

and Use) Regulations 1986

The legislation which covers the transportation of the Grange 3m LDT

equipment on the UK public highway when coupled to the tractor

is The Construction and Road Use Regulations (C&U) 1986. The

requirements to apply are as follows;

i) Check the dimensions (width and length) and mass (kg) of and 2nd

stage cultivation/seeding equipment which are coupled to the

Grange 3m LDT equipment.

The maximum permitted masses and vehicle dimensions for

transporting the Grange 3m LDT and associated 2nd stage

cultivation/seeding equipment is as follows (Not including

the tractor);

i) The maximum permitted mass of a trailed implement is

14,230kg. The operator’s manual for the 2nd stage cultivation/

seeding equipment must be checked to verify its mass, including

any restrictions on transportation on the public highway with

material in a seed hopper.

ii) A maximum width of 2.55m

iii) A maximum length of 15m.

The speed limit and required notification to the authorities

are as follows;

i) If the overhang of the Grange 3m LDT equipment in the transport

position exceeds 305mm from the widest point of the tractor wheel

/ tyre setting, a width marker board is required.

ii) As the transport width of the 3.0m LDT equipment is between

3.0m and 3.5m with or without any 2nd stage cultivation / seeding

equipment coupled up, the maximum speed limit of the tractor and

the Grange 3m LDT equipment is 20mph. If the planned journey

exceeds 5 miles, or the speed limit on any of the public highway is

40mph or less, the operator must notify the Police in advance of

the journey.

12.0 Getting started in the field

Note the requirement for the use of appropriate PPE (gloves, overalls and safety

boots) as components such as cutting discs have sharp edges.

Once arriving in the field, the machine must be set-up correctly for the cultivation

routines. Stop the movement controls of the tractor, apply the handbrake,

stop the engine

i)

Using the tractor hydraulics lower the three point linkage to position the rear

attachment of the hitch of the Grange 3m LDT to resemble the same height

as the tractor drawbar. Refer to the tractors operators’ manual for the safe

operation of externally mounted hydraulic controls.

Please note the three

point linkage of the tractor now needs to be locked in position. The

Grange 3m LDT is now setup in the working position, ref fig 11.0. Stop the

movement controls of the tractor, apply the handbrake, stop the engine and

remove the key.

ii)

There is one disc ram located centrally under the headstock. There are two

main beam lift rams. The disc ram rotates the cutting discs out of work,

whereas the main beam rams elevate the low disturbance legs out of the

ground eliminating the need to raise the tractor three point linkage on the

headland turns.

iii) Assess the soil conditions and starting with the single disc ram apply the

required number of spacers, ref fig 12.0. Following on with the main beam lift

rams; apply a consistent number of spacers to each ram as illustrated in fig

13.0. Each spacer is colour coded to represent different thicknesses. For safe

and efficient operation of the Grange 3m LDT, the two main beam rams must

be operating to an even depth. The low disturbance legs can cultivate to a

depth of 300mm.

iv) When commencing work the cutting discs need to enter the ground between

50mm and 75mm.

v)

Return to the tractor, restart the engine and activate the tractor auxiliary

hydraulics to engage the discs and lower the main beam to the ground whilst

engaging a slow forward speed.

vi) In the event that adjustments need to be made in the field for the Grange

3m LDT working depth, apply the following procedure; Firstly raise the main

beam fully and rotate the discs out of work. Stop the movement controls

of the tractor, apply the handbrake, stop the engine and remove the key.

The adjustment of the spacers can be performed safely with the operator

positioning themselves at the front of the Grange 3m LDT.

11.0 Transport safety

Before undertaking transport of the Grange 3m LDT equipment

on the public highway refer to the details in section 11.1 with

regards to road legislation.

Please refer to section 9.0 for the correct tractor front counterbalance

when connecting 2nd stage cultivation / seeding equipment.