11

10

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

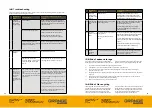

TABLE 1.0

Safety decal

Meaning

Safety Decal

Meaning

Crushing of toes or

foot. Force applied from

above.

Do not use manual

lifting techniques.

Wear protective gloves

Grease lubrication

connection

Specified lifting

point. Attachment

with approved lifting

component.

In the event of safety decals wearing away please contact the manufacturer for replacements.

5.0 Equipment specifications

The equipment specifications are an important reference to establish the correct

tractor specification and front ballast requirements to ensure stability.

Equipment

specification

Hitch Category

to tractor

connection

Mass (Kg)

Working

width (m)

Transport

width (m)

Machine length

(m) from 3 point

linkage to rear

clevis

3m LDT

Cat III / Cat IV

1250

3.0

3.0m

1.49m

Equipment

specification

No of legs / leg

spacing.

Minimum tractor auxiliary

hydraulic connection

requirements.

Recommended tractor power

output (hp)

3m LDT

6 / 0.5m

1 x Double acting

hydraulic service.

150hp +

4.0 Safety decals

Safety decals are located on the machine to inform the operator of the appropriate

procedures to prevent harm to themselves or others persons nearby. These refer to the

following procedures where operator interaction with the Grange 3m LDT is required;

i) Unloading from the transporter on delivery to the customer.

ii) Assessing the correct tractor specification and front ballast requirements.

iii) Hitching the Grange 3m LDT equipment to the tractor.

iv) Coupling up 2nd stage cultivation on the rear two point lower linkage or

clevis drawbar.

v) Planning for transportation on the public highway of the Grange 3m LDT equipment

and where required 2nd stage cultivation/seeding system to the field.

vi) Setting the Grange 3m LDT equipment and 2nd stage cultivation/seeding systems

up for the soil working conditions.

vii) Undertaking inspection and maintenance and replacement of wearing part

procedures on the Grange 3m LDT equipment.

Table 1.0 summarises the safety decals in use on the Grange 3m LDT and their

meanings.

The colour definitions for the decals are as follows;

i.

Yellow: Caution: Hazard potential and where appropriate keep clear of

moving parts.

ii.

Blue: Mandatory: Requirement to undertake an action.

iii. Red: Prohibited. Do not undertake depicted action.

TABLE 1.0

Safety decal

Meaning

Safety Decal

Meaning

General hazard warning

sign.

Switch off engine

and remove key

before undertaking

maintenance or

repair work.

Potential for injection of

hydraulic fluid under high

pressure.

Stay a safe distance from

the machine.