5

4

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

This operator’s manual is for retention with the

machine during all times of operation. If the

machine is to be sold onto other users, please

provide the manual as part of the transaction.

In the event that the manual becomes damaged

beyond effective use, please contact the

manufacturer for updated copies, stating the

machine specification and serial number.

The contents of this operator manual are correct

at the time of print but may be subject to additions

and change at any time in the future.

This manual refers to the following Grange

Machinery Ltd equipment;

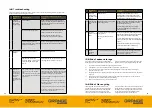

1.0 Identification of manual

MACHINE TYPE

WORKING WIDTH

SERIAL NO’S

3m LDT

3m

The serial plate is located on the headstock of the Grange 3m LDT, as detailed in the photo below.

The Grange 3m LDT is designed for primary

cultivation practices where soil pans need to be

removed to allow root penetration and water

infiltration. The discs cut through any surface

trash and allow the legs to alleviate the subsurface

compaction with minimal disturbance to the top soil

and reducing moisture loss.

The Grange 3m LDT incorporates both a lower

linkage arm assembly and a clevis hitch on the

rear to allow secondary cultivation or seed drill

equipment to be attached. Hence providing the

solution for one pass seed establishment.

1.1 Introduction to the Grange 3m LDT

1.2 Meanings and definitions

Throughout the manual various definitions are used.

Their meanings are referred to here;

REFERENCE TERM

MEANING

2nd stage cultivation / seeding

equipment

Cultivation or seeding equipment coupled to the Grange 3m LDT

machine via the clevis hitch or 2 point linkage.

Ballast

Additional weights or other equipment to ensure tractor stability

when the Grange 3m LDT equipment is in operation.

Qualified and experienced

A person (operator) who has received appropriate instruction

and where necessary undertaken a qualification for operating the

relevant machinery. The operator understands the health and safety

procedures for use of the Grange 3m LDT.

Machines life cycle

The use by the owner of the Grange 3m LDT from delivery by

the manufacturer to its end of operational life and subsequent

authorised disposal.

The hazard symbol is used throughout the manual to highlight areas of

importance to the operator. Please note the specific content referred to in

these sections.

In the event of requiring further support beyond the content of this manual, please

contact the manufacturer at;

Grange Machinery Ltd, Sproatley Grange, Hull, HU11 4PT

www.grangemachinery.co.uk : 01482 815711

SERIAL PLATE LOCATION