31

30

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: [email protected]

W: www.grangemachinery.co.uk

Before undertaking maintenance on the Grange 3m LDT ensure

the following safety procedures are put in place.

i) Never undo hydraulic pipes until all the pressure is released.

ii) Identify whether the maintenance activity requires the

Grange 3m LDT equipment to be raised off the ground.

If so any 2nd stage cultivation/seeding equipment will need

to be safely uncoupled.

iii) Locate suitable hard standing which can take the full weight of

the Grange 3m LDT. If requiring the 3m LDT machine to be raised

off the ground, apply safe chocking methods, such as adjustable

axle stands with adequate load capacity. Refer to the equipment

specification; Section 5.0.

iv) Stop the movement controls of the tractor, apply the handbrake,

stop the engine and remove the key.

v) Wear appropriate PPE.

vi) Select the correct workshop tools.

vii) Remove any residual mud or other extraneous material from

the machine.

viii) Use lubrication spray oils to free up bolts to facilitate ease

of removal.

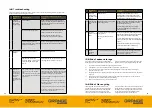

13.1 Replacing shear bolts

FIG 15.0 SHEAR BOLT WITH SHEAR PLANE

RED LINE – LOWER LEG (15MM)

YELLOW LINE – UPPER LEG (20MM)

FIG 16.0 SHEAR BOLT LOCATION

When replacing the points use suitable solid level

ground e.g. concrete/tarmac, to avoid the risk of

sinking and potential injuries whilst changing the

points as well as potential damage to tungsten

tipped points. The implement must be raised on the

tractor linkage and the tractor engine turned off and

handbrake applied.

It is important to support the weight of the Grange

3m LDT with appropriate axle stands to enable safe

access to the points. Please be aware it is forbidden

to work under a suspended load without the

adequate support.

Wear appropriate PPE which is safety glasses and

gloves. In addition the use of a safety bump cap will

prevent any inadvertent contact by your head with

the frame.

Once you are confident that you have met the safety

standards required you can proceed.

Unbolt the single fixing (M10 x 40mm long bolt) from

the worn point to free the point. A new point can

then be replaced into the same position using the

same size fixing. Ensure the bolt is fully tightened,

ref Fig 17.0.

When you have finished replacing the points,

remove the axle stands supports/chocks in order

to proceed.

13.2 Replacing points

FIG 17.0 NEW POINTS FITTED AND SECURING CONNECTIONS