9

SERVICE

REQUIRED TOOLS

Torque wrench

Bench vise, with soft jaws

Hammer

Rubber mallet

Razor or other sharp tool

8 mm (5/16 in.) dia. brass rod

8 mm, 11 mm, 15 mm, 25 mm,

3/4 in. and 7/8 in. open–end wrenches

17 mm box or socket wrench

22 mm crow’s–foot wrench

Adjustable wrenches

24 in. adjustable wrench

Thread lubricant

Anaerobic thread sealant

DISCONNECTING THE DISPLACEMENT PUMP

KEEP HANDS AND FINGERS AWAY FROM THE

PRIMING PISTON DURING OPERA TION AND

WHENEVER THE PUMP IS CHARGED WITH AIR

to reduce the risk of injury!

On the pump down-

stroke the priming piston extends beyond the intake

cylinder to pull the material into the pump. The prim-

ing piston works under extreme force. During opera-

tion and whenever the pump is charged with air, the

priming piston can severely injure or amputate a

hand or finger, or break a tool, caught between it and

the intake cylinder. Always follow the

Pressure Re-

lief Procedure Warning

on page 8, before check-

ing, clearing, cleaning, flushing or servicing any part

of the pump.

The air motor piston (located behind the air motor

plates) also moves when air is supplied to the motor.

NEVER operate the pump with the air motor plates

removed. Before servicing the pump, follow the

Pressure Relief Procedure Warning

on page 8, to

prevent the pump from starting accidentally.

WARNING

1. Flush the pump if possible. Stop the pump at the bot-

tom of its stroke. Follow the

Pressure Relief Proce-

dure Warning

on page 8.

2. Disconnect the air hose. Hold the fluid outlet fitting

(7) with an adjustable wrench to keep it from being

loosened while you disconnect the fluid hose. Re-

move the pump from its mounting. Note the relative

position of the pump’s fluid outlet to the air motor’s air

inlet.

3. Using an adjustable wrench, unscrew the coupling

nut (104) from the connecting rod (103). Remove the

coupling collars (105). Take care not to lose or drop

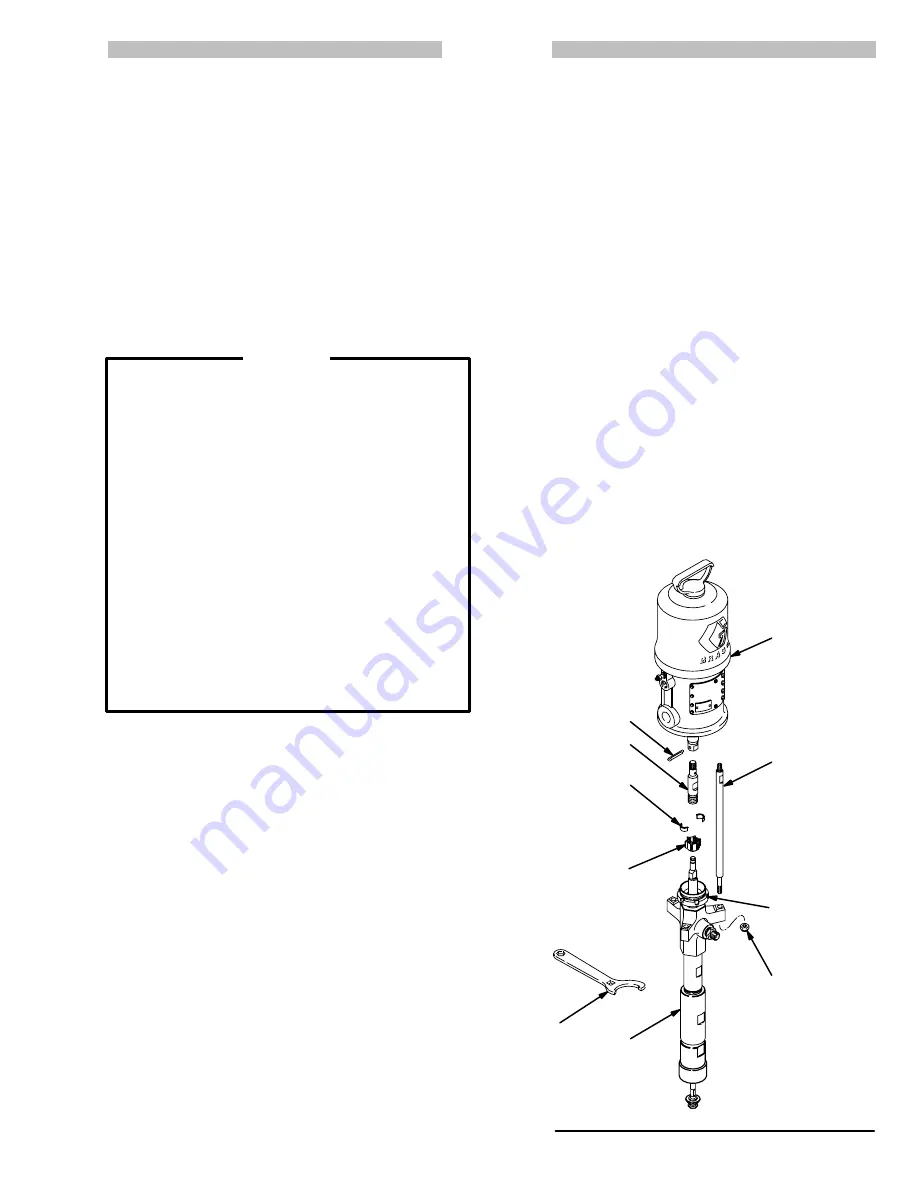

them. See Fig 3.

4. Hold the tie rod flats with an 11 mm wrench to keep

them from turning. Use the wrench (1 13) provided

with the pump (or a 17 mm box or socket wrench) to

unscrew the tie rod locknuts (106) from the tie rods

(102). Carefully pull the displacement pump (107) off

the air motor (101).

5. Refer to page 10 for displacement pump service. To

service the air motor, refer to the separate air motor

manual, supplied.

RECONNECTING THE DISPLACEMENT PUMP

1. Orient the pump’s fluid outlet to the air motor’s air in-

let as was noted in step 2 under

Disconnecting the

Displacement Pump.

Position the displacement

pump (107) on the tie rods (102). See Fig 3.

NOTE:

If you removed the tie rods (102) from the air mo-

tor (101) or air motor adapter plate, reinstall

them using an 11 mm wrench. Torque the rods to

20–25 N.m (15–18 ft–lb) on Model 222–783, and

34–41 N.m (25–30 ft–lb) on Model 222–782.

2. Screw the locknuts (106) onto the tie rods (102) and

torque to 34–41 N.m (25–30 ft–lb), using the wrench

(113) provided (or a 17 mm box or socket wrench).

3. Place the coupling nut (104) on the displacement

rod, then place the coupling collars (105) in the nut.

Screw the coupling nut onto the connecting rod (103)

loosely. Hold the connecting rod flats with an adjust-

able wrench to keep it from turning. Using an adjust-

able wrench, torque the nut to 41–48 N.m (30–35 ft–

lb).

4. Using a torque wrench in the square hole of the

supplied wrench (113), torque the packing nut (2) to

27–34 N.m (20–25 ft–lb).

5. Mount the pump and reconnect all hoses. Reconnect

the ground wire if it was disconnected during repair.

Turn on the air to the motor and run the pump slowly.

6. Fill the packing nut/wet–cup 1/3 full of Graco Throat

Seal Liquid or compatible solvent.

Fig 3

101

103

105

107

102

TORQUE TO

20–25 N.m

(15–18 ft–lb)

ON MODEL

222–783;

34–41 N.m

(25–30 ft–lb)

ON MODEL

222–782

106

TORQUE TO

34–41 N.m

(25–30 ft–lb)

104

TORQUE TO

41–48 N.m

(30–35 ft–lb)

108

2

TORQUE TO

27–34 N.m

(20–25 ft–lb)

0204A

113

Summary of Contents for Metric CHECK-MATE 200

Page 26: ...26 NOTES...

Page 27: ...27 NOTES...